The most complete LED light strip knowledge in history, continue reading to learn more

1. What is the LED Strip Light?

Definition:

Led strips are made LEDs assembled on a strip-shaped FPC (Flexible Printed Circuit) or PCB(Printed Circuit Board). It is named led strip as its shape like a long strip. It is a new type of LED lighting Product.

Very flexible, easy to install and maintain, it has a wide range of applications, won wide acclaim from users and lead the new trend of LED linear lighting. It is another feat of the LED lighting industry.

Craftsmanship:

Use a narrow and long flexible circuit board or rigid circuit board as the main body of the light strip. Fix the SMD LED and the SMD resistor on the FPC board by patch reflow soldering technology, and then solder a wire to the one end of the FPC board to connect the power supply and that’s made a led light strip.

Features:

- It uses a safer 12V/24V low-voltage DC power supply.

- Flexible cut length for easy use.

- Self-adhesive tape on the back for easy installation.

- Provides a variety of fixed and variable colors and brightness to suit different lighting applications.

- 50000 hours long life.

2. Led light strip classification

According to the voltage, it can be divided into:

1. Low-voltage DC led strip, which is powered by a DC constant voltage power supply.

a, Conventional DC5V/12V/24V light strip.

The DC5V led strip is powered by a DC5V power supply. Mainly used by the USB interface power supply, often used as led TV backlighting.

DC12V/24V led light strip is using DC12V or DC24V power supply. Widely used in various indoor and outdoor led linear lamps, led linear lighting, auxiliary lighting, and decorative lighting scenes.

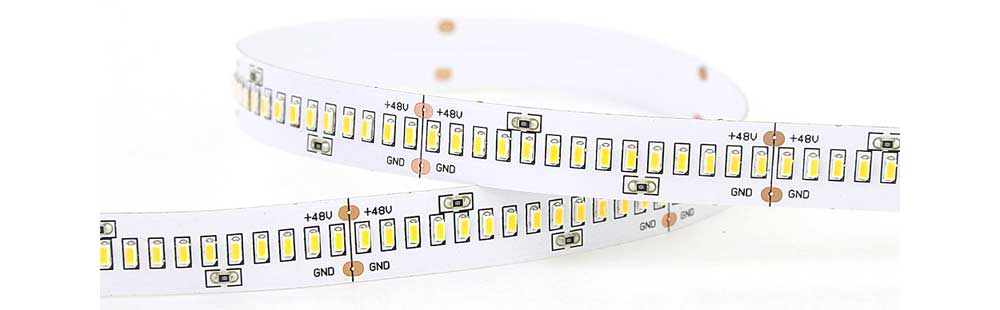

b, Special voltage DC36V/48V led light strip

The power supply is limited to 36V or 48V for some special applications

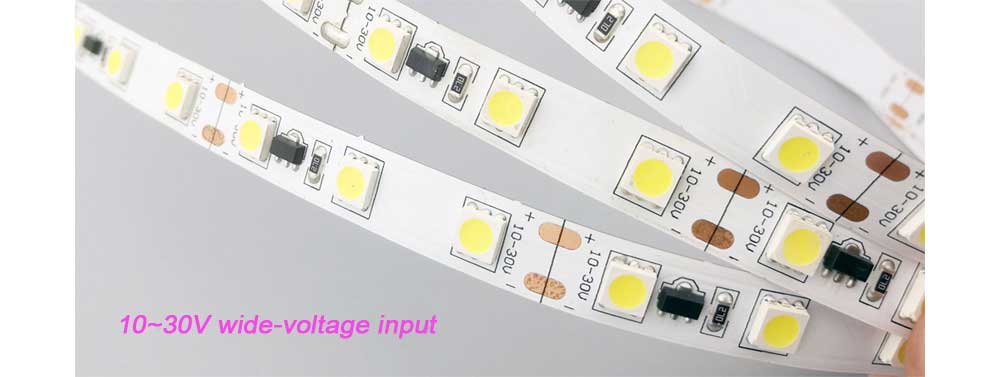

c, Wide voltage input DC10-30V light strip

This type of led strip is mainly used in scenes where the DC power supply voltage output is unstable.

For example, in small ships, because of the use of diesel silicon rectifier generators, it will cause the output voltage to fluctuate between DC10-30V. In this case, the DC10-30V wide-voltage lamp strip can be directly used.

2. High voltage AC110V~240V light strip

It uses a high voltage AC power supply. This kind of light strip is mainly used for outdoor lighting decoration, or used for temporary engineering lighting scenes. So it can be used as a flexible work light.

Because it is dangerous to use the high-voltage AC power supply, so it is used in places that are not accessible by human hands. Such as ceilings lighting, trees decorative lighting, etc.

According to the application scenes it can be divided into:

1. Auxiliary lighting strips, using conventional monochromatic lamps. Such as wardrobe cabinet lighting, bedroom background lighting, showcase shelf lighting and so on.

2. Decorative lighting strips, using conventional RGB led strips or RGB IC strips. Such as bar ceiling, KTV wall decoration, wine cabinet decoration, Building lighting, bridge lighting, etc.

3. Linear main lighting led strips, made of linear main lighting fixtures by using conventional monochromatic led strips, combined with aluminum profiles or silicone neon sleeves.

4. Plant growth lighting led strips, using strips made of Special wavelength LED, provide special light to promote plant growth.

5. Sterilization lamp belt for the medical germicidal lamp, using deep ultraviolet LED.

According to the light color can be divided into:

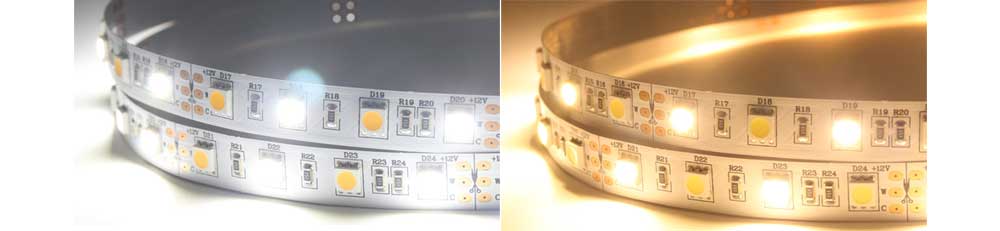

1. Monochrome led strips, such as white color, warm white, red, green, blue, yellow, orange, amber, pink, etc.

Because of the white and warm white is not accurate to describe the color of light, so it is usually replaced by color temperature in the light strip, such as 2700K, 3000K, 4000K, 6000K.

2. RGB led light strip, by synthesizing R, G, B three primary color chips into one LED, so it can separately emit three kinds of the light color red, green, blue.

The color light can also be illuminated by three chips together and combined into white color light. If you add an RGB led strip controller, you can achieve a changeable light in sequence and flickers. such as red, green, blue, and white.

3.RGA light strip, similar to the RGB light strip, the only difference is that the RGB LED’s Blue Chip is replaced by the Amber chip in the RGA lamp bead.

4. Double-color light strip, by using any two colors of LED to combine the production of led light strips, the most common is white color + warm white, as well as white color + blue color, white color + red color.

5.RGBW/RGBCCT/CCT led light strip

CCT here means Control Color Temperature, which means that the color temperature of the led strip lights can be adjusted to change between warm white color and white color.

a, The CCT led strip is made from LED in both white and warm white colors. White light color temperature is 2700K, the warm white temperature is 6500K, commonly used lamp beads are 2835 single cup LED or 5050 single cups LED.

The led strip light can have a color temperature adjustment range of 2700K~6500K during use, which makes the color temperature selection in the lighting application scene more flexible.

b, The RGBW led strip light is made of RGBW four-in-one LED. The RGBW led strip can not only achieve the color change effect of the RGB led strip, but also can bring another monochromatic light to meet the more demanding monochromatic lighting requirements.

c, The RGBCCT led strip light is an upgraded version of the RGBW led strip.

The RGBCCT led strip light is made of a five-in-one LED. It does not have a fixed color temperature like white color light in RGBW led strip but has two color temperature led chips: a warm white color light, usually 2700K, and a white color light, the color temperature is usually 6500K.

It covers all the functions of both RGB and CCT led strips, giving a more flexible and friendly lighting experience.

6. The special color wavelength, Such as 390nm, 420nm, 470nm, etc, mainly used for special lighting applications.

According to whether the LED has an IC chip can be divided into:

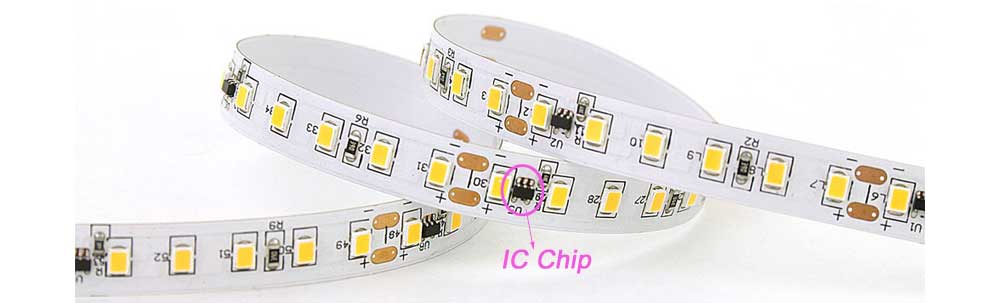

1. Conventional IC led strip, in addition to the LED and the resistor, the FPC board of this type has a constant current IC chip on it, to control the current of each group of LED to be consistent.

Reduce the impact of plate pressure drop on led strip illumination, Keep the brightness of the head and tail of the led strip consistent.

This constant current IC chip can also be integrated inside the LED, which can produce another IC led strip, that is, no resistance and no IC chip.

That is, from the appearance, the led strip on the FPC board has only LED, there is no other electronic component. This solution can make the brightness of the led strip more consistent, the appearance is simpler, the LED arrangement is more flexible, and it can be used as a solution for the high-density led strip.

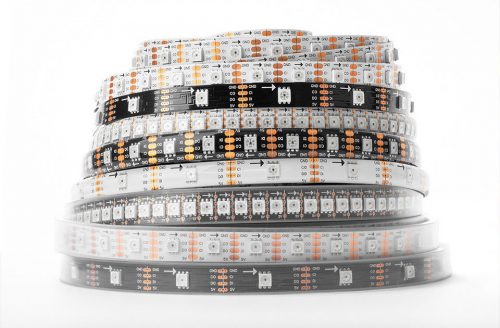

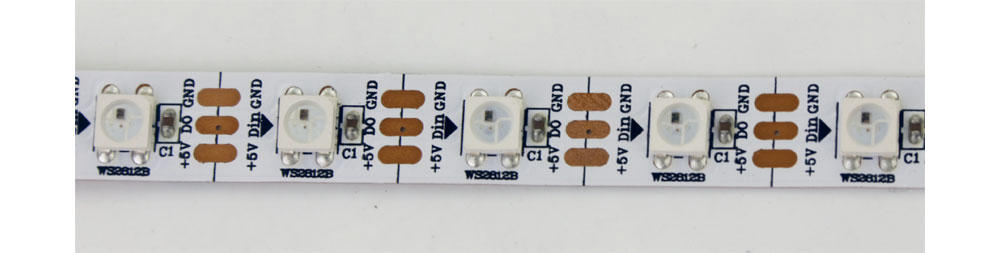

2. Addressable IC led strip, the IC chip on the strip is not an ordinary constant current IC, but an IC chip can be regarded as a pixel.

This IC chip has its own address and can be controlled by receiving controller signals. The signal sent to it can control the level output for different positions of the LED, such as flashing, chasing, jumping, clockwise horse racing, counterclockwise horse racing, monochrome horse racing, color-changing horse, single chasing from head to Tail, flowing water, simulated lightning and the like.

The effect of the change of the light strip can be written according to the needs of the customer and can be displayed in the form of a screen, text, letters, pictures, animations, and the like. Common IC chips on the market mainly include WS2811, WS2812, SK6812, P943, Ap102, DMX512 and so on.

The LEDs used in the addressable led strip can be monochromatic LED, RGB LED, or RGBW LEDs.

According to the board material, it can be divided into the flexible led light strip and rigid led light strip

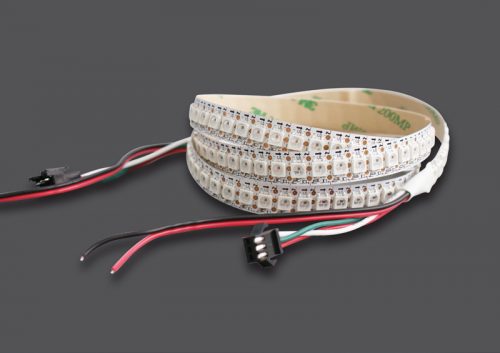

1. Flexible led light strip, it is made of the flexible FPC circuit board, can be bent, folded, wound, Overall flexibility and light, backed with 3M self-adhesive tape, easy to install.

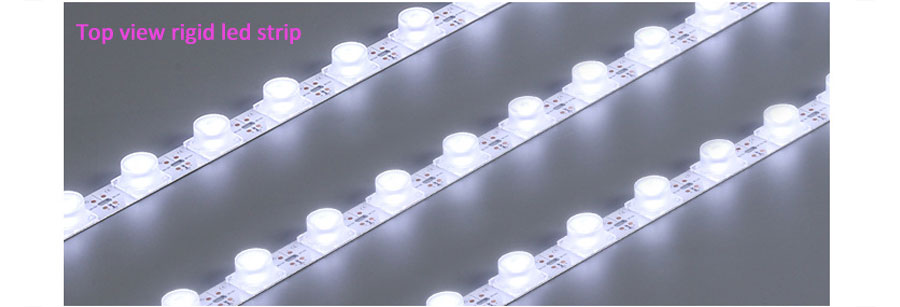

2. Rigid led strip light, made of the aluminum substrate or fiberglass board, it can’t be bent, mainly used for straight linear illumination scenes.

According to the arrangement characteristics of the LED, it can be divided into a top view light strip, side view light strip, one side view one top view strip, multi-row led strip, high-density led strip, short unit cut led strip, S-type led strip.

1. Top view led light strip, the most common light strip is this kind strip, the beam angle is 120 degrees, the flexible PCB board is attached with SMD LED on the front, and the back is 3M self-adhesive.

2. Side illuminating strips, mainly made of 3014 side illuminating LED, for special installation requirements.

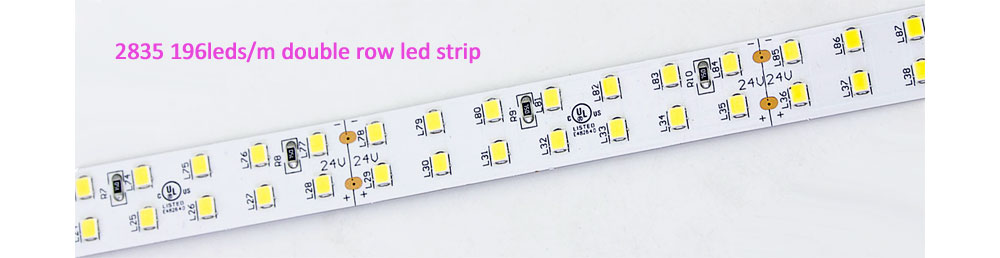

3. Multi-row led strip light, it’s one FPC board with two or more rows of LEDs for higher brightness. This strip is mainly used in linear main lighting fixtures as a light source.

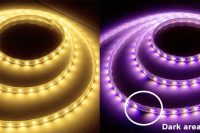

4. High-density led strip, by increasing the density of the LED on the led strip, the brightness can be increased, and the dark area problem caused by the linear strip illumination can also be reduced. This strip of light is primarily used to match specific aluminum channel profiles for no dark area lighting application.

5. Short-unit cuttable led strips, usually led strips are 3 LEDs or 6 LEDs for a group of loops, 2.5cm, 5cm, or 10cm for a cutting unit. The Short-unit cuttable led strip can make one LED or two LEDs as a set of loops, and 1cm or 1.25cm is a cutting unit.

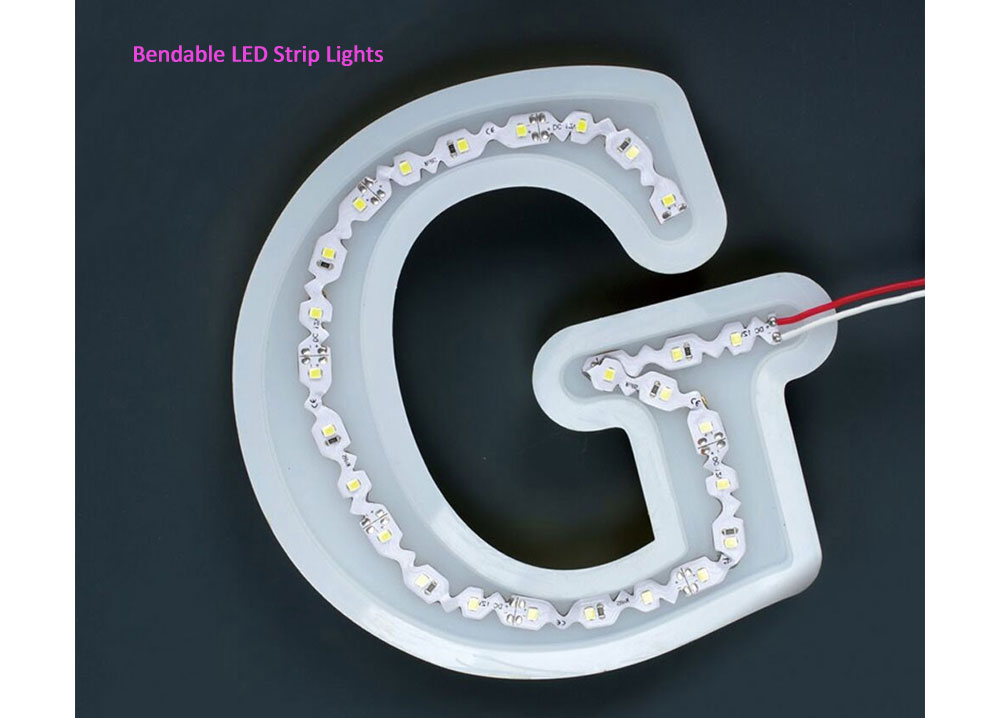

6. S-type LED Strip, also called Bendable led strip, zigzag led strip. The led strip can be bent on one plane, thereby folding out various shapes, mainly used for billboard light boxes, luminous characters, etc.

3. The components of the led light strip

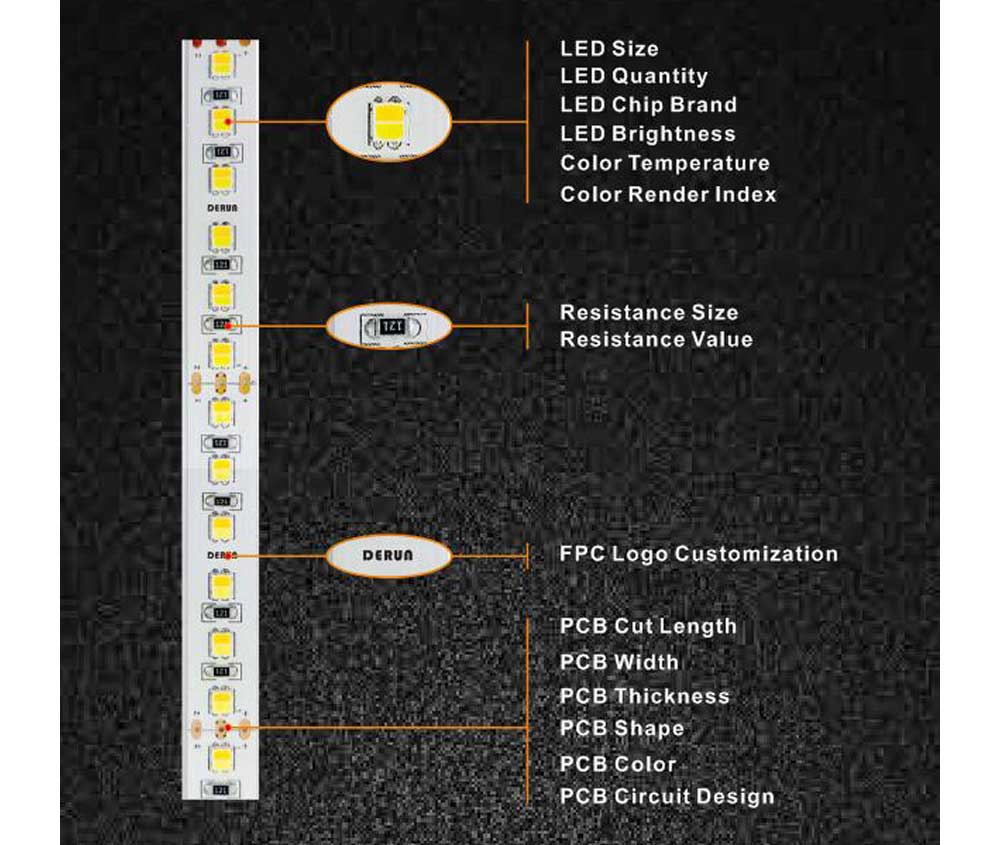

The led light strip is mainly composed of SMD LED, SMD resistors, flexible PCB boards, and wires, as shown in the figure.

1. The LED source type used for led strip

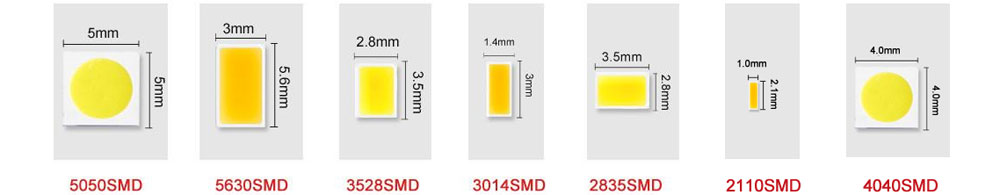

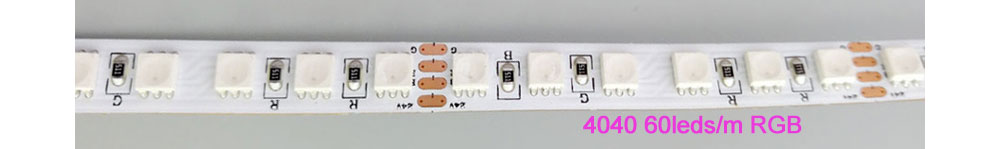

The LED source is mainly: 3528, 5050, 2835, 3014, 2216, 5630, 5730, 2110, 4040, and so on.

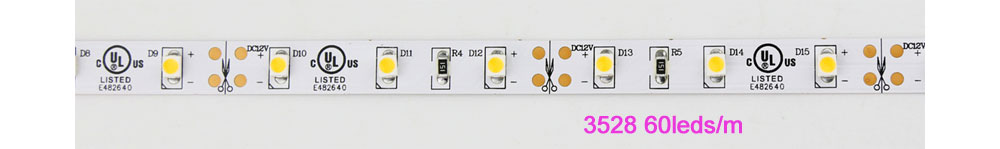

3528 led strip, using 3528 LED (LED size 3.5mmx2.8mm) as the light source, the brightness of each 3528 LED is 7-8lm, the power of a single LED is about 0.08w, 3528 led strip often used a number of LED is 30LEDs/m, 60LEDs/m, 120LEDs/m, 240LEDs/m.

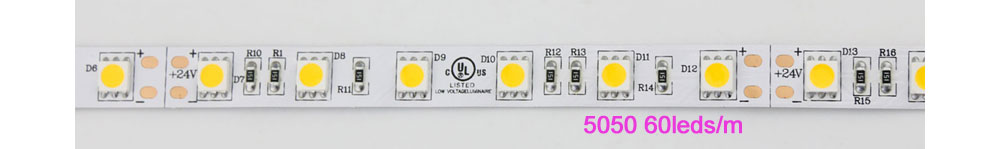

5050 led strip light, LED size: 5.0mmx5.0mm, Lumen: 24-26lm, Power: 0.24w, LEDs QTY/M: 30LEDs/m, 60LEDs/m, 120LEDs/m.

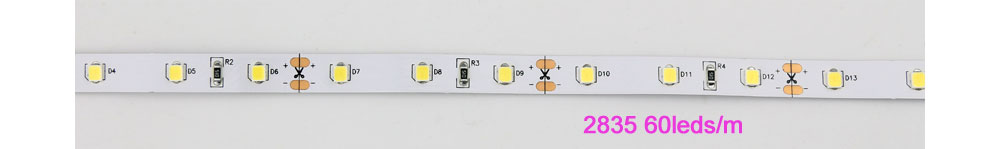

2835 led strip light, LED size: 2.8mmx3.5mm, Lumen: 24-26lm, Power: 0.2w, LEDs QTY/M: 30LEDs/m, 60LEDs/m, 120LEDs/m.

3014 led strip light, LED size: 3.0mmx1.4mm, Lumen: 10-12lm, Power: 0.1w, LEDs QTY/M: 120LEDs/m, 156LEDs/m.

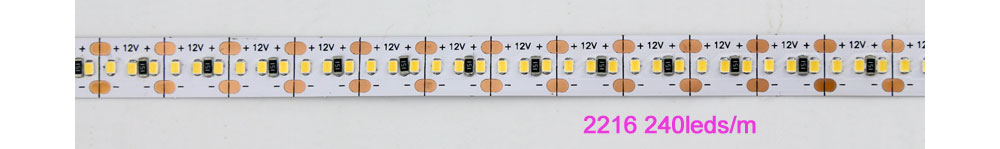

2216 led strip light, LED size: 2.2mmx1.6mm, Lumen: 10-12lm, Power: 0.1w, LEDs QTY/M: 120LEDs/m, 240LEDs/m.

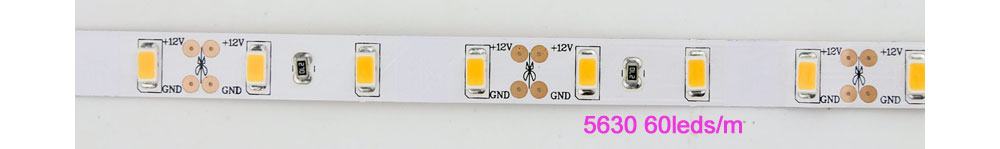

5630/5730 led strip light, LED size: 5.6mmx3.0mm, Lumen: 50-55lm, Power: 0.5w, LEDs QTY/M: 30LEDs/m, 60LEDs/m.

2110 led strip light, LED size: 2.1mmx1.0mm, Lumen: 10-12lm, Power: 0.1w, LEDs QTY/M: 240LEDs/m, 360LEDs/m, 576LEDs/m.

4040 led strip light, LED size: 4.0mmx4.0mm, Lumen: 24-26lm, Power: 0.2w, LEDs QTY/M: 60LEDs/m, 120LEDs/m.

2.The manufacturing process of led strip lights PCB board

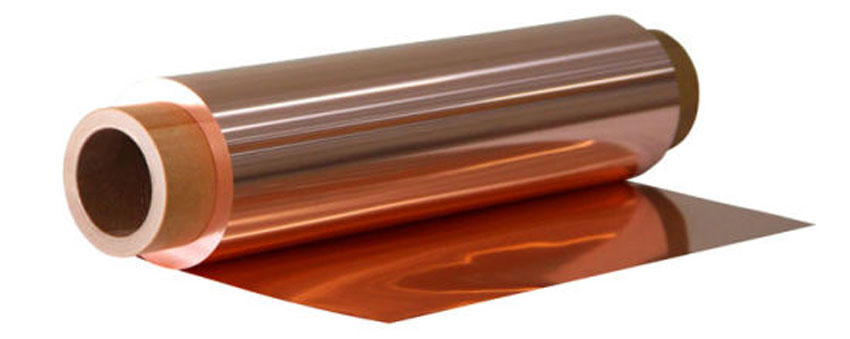

It is divided into rolled copper and electrolytic copper.

The PCB made by the rolled copper process has better integrity, better electrical conductivity, and thermal conductivity, but at a higher cost;

The PCB made by the electrolytic copper process is slightly worse in overall performance, but will not affect the normal use of the light strip.

And because of the convenience and maturity of its production process, it has won the favor of a large number of customers, and the production cost is also lower.

3. The thickness of the led light strip PCB board

The amount of current that the light strip can carry determines the width and thickness of the PCB of the light strip. When the current through the PCB increases to a certain limit, it is necessary to widen or thicken the PCB to ensure that the led light strip works normally.

The width of common light strips is 8mm, 10mm, 12mm, and the thickness of common light strips is 2oz, 3oz, 4oz.

Of course, the thicker the board, the worse its flexibility, and there is a risk of pad cracking and board breakage during the winding process.

Therefore, if the working current of the lamp strip is large, it is not that only through thickening the PCB board that the led strip light can work normally. Instead, a variety of potential impact factors should be combined to rationally design the light strip circuit in order to produce a qualified light strip product that meets customer needs.

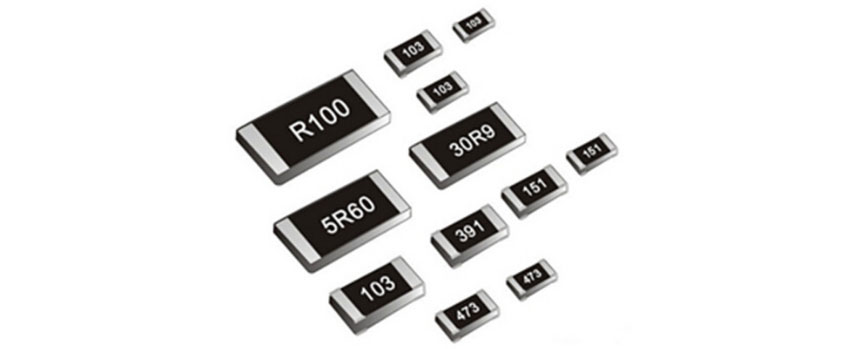

4. The chip resistor used in the light strip

The conventional lamp strip uses 1206 chip resistor (size: 3.2mmx1.6mm), the max power is 0.25w.

There are also some led light strips with relatively narrow widths. Due to the limited space of the PCB board, 0805 chip resistors (size: 2mmx1.25mm) will be used, and the max power is 0.125w.

5. Outlet method of the led light strip

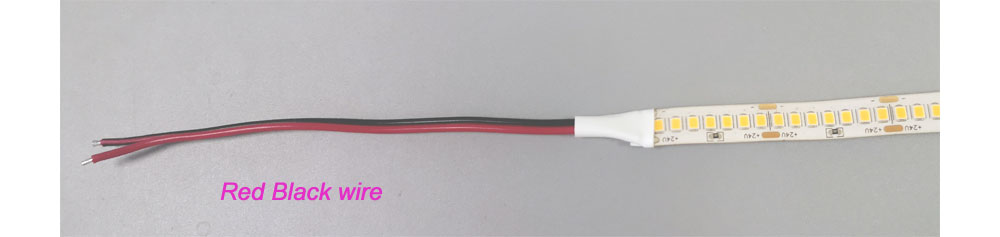

The end of the conventional monochrome light strip will use 20awg red and black wire as the power supply line, and a thin wire will cause a great safety hazard. Because the voltage of the light strip is low, usually 12V or 24V, then the current of the 12V-12W light strip will reach 1A, and the current of the 12V-120W light strip will reach 10A.

So, when choosing the connector wire of the led strip, you should make sure that the wire can carry the working current of the led strip lights. Otherwise, it may cause the power supply line of the led strip to heat up, scorch the connector, or even cause a fire.

The end of the conventional RGB light strip will use RGB-4pin as the power supply line, and the thickness of the wire is 22awg.

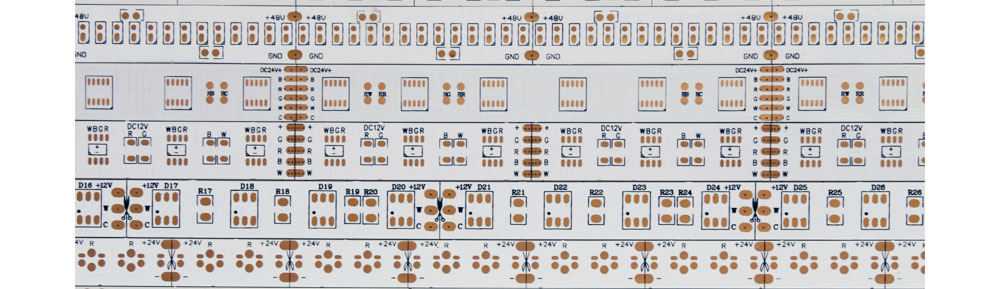

6. The size of the PCB pad of the lamp strip

The PCB pad is divided into LED pad, resistance pad and shear port pad

The LED pad and the resistance pad can not be designed too small, otherwise, it will lead to the unreliable LED PCB circuit, and will happen in the situation of dead light when used for a long time.

The design of the PCB shear port pad is too small or too narrow, which may lead to weak welding of the power supply line of the led strip; if it is too large, or too much tin is added, the joint solder joint may be too heavy, and long-term use may cause the solder joint to fall off and affect The led light strip use.

7. Silkscreen and logo

The led strip is printed with text or logo on the surface of the PCB

+ On behalf of the positive pole

– negative pole

R1, R2 – resistance

DC5V, DC12V, DC24V – working voltage

R – redlight chip

G – green light chip

B – Blue light chip

W – white light chip

UL – UL certification mark

CE – CE certification mark

Di – signal input line

Do – signal output line

GND – negative wire

VCC – positive wire

IC model used by WS2812

8. The back-adhesive used for the led strip light

IP20 non-waterproof led light strips and IP54 glue-proof waterproof light strips are attached with self-adhesive tape on the back of the light strips when they leave the factory for easy installation.

Usually, the adhesive tape used for the light strips is the self-adhesive tape produced by 3M Company. The most common adhesive tape is 300lse

In addition, there are white glue, blue thermal conductive tepe, red VHB tape, etc. Each type of tape has different viscosity.

Be sure to choose a tape that suits you. Otherwise, the light tape may not be enough adhesive strength because of long-term use and cause the light strip to fall off.

In addition, in order to reduce the production cost of the light belt, some businesses will choose fake 3M tape.

The appearance of this tape is not much different from the real 3M tape. If you don’t pay attention, you can’t distinguish it. This kind of tape is not sticky enough, and it will easily fall off after long time use.

Therefore, when you buy a led strip light, you must polish your eyes and distinguish carefully, not to be fooled by the manufacturer.

4. Introduction of the brightness of the LED strip

There are many factors that affect the brightness of led lights, and we will introduce them one by one.

1. The brightness of different types of lamp beads is different.

3528-0.08w-The brightness of a single lamp bead is about 7-8lm

5050-0.24w-24-26lm

2835-0.2w-24-26lm

3014-0.1w-10-12lm

2216-0.1w-10-12lm

5630-0.5w-50-55lm

2110-0.1w-10-12lm

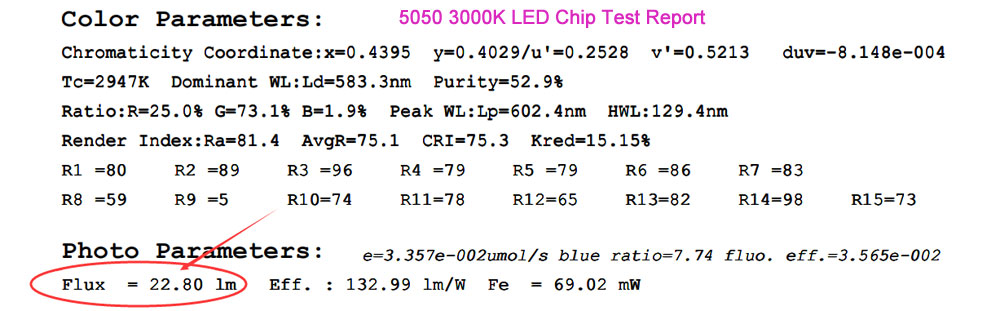

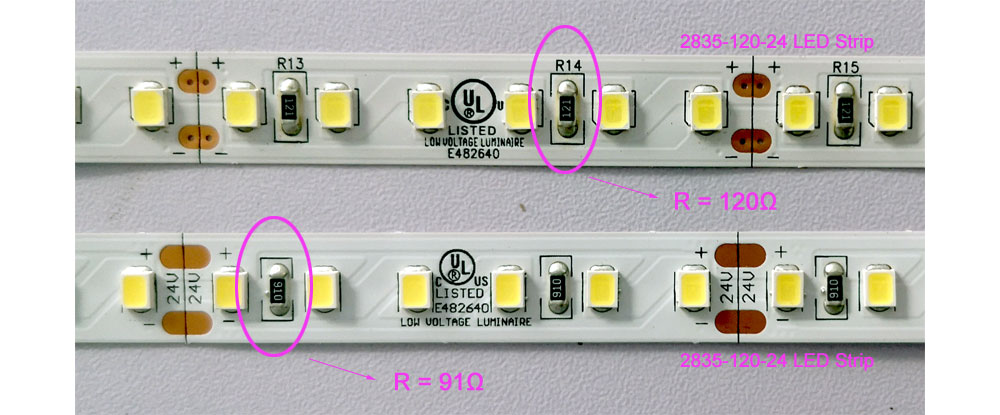

2. USE the same LED chip but different resistances in same PCB circuit, the led strip light’s brightness is different

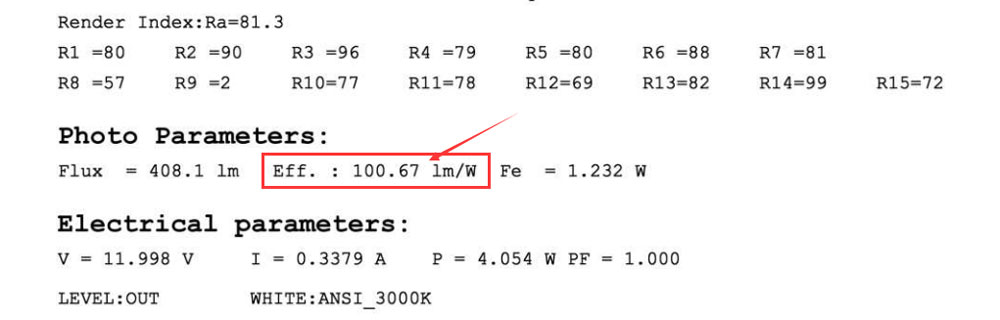

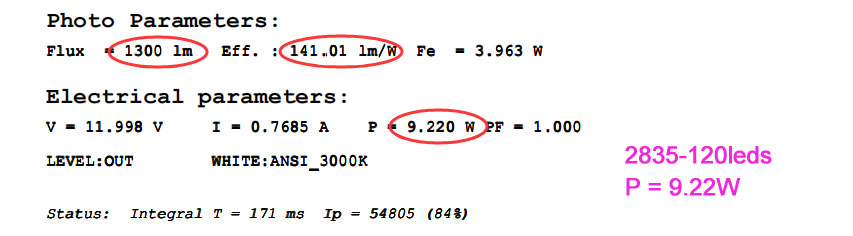

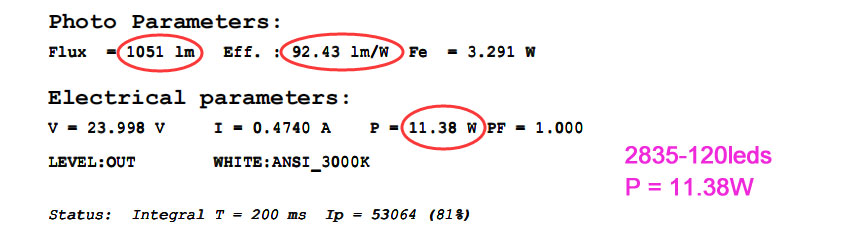

For example, the following led strips are 2835-120 LEDs/M 3000K Color, and the circuit scheme they choose is exactly the same, and the same LED Chip is also used.

However, the resistance of the first light strip is 120 ohms, and the resistance of the second light strip is 91 ohms, then the second light strip is brighter than the first.

Of course, it does not mean that the smaller the selected resistance, the better. Each circuit scheme corresponds to a minimum limit resistance value. If it is lower than this resistance value, the light strip will be burned due to overheating.

Therefore, according to actual needs, the purpose of adjusting the brightness of the whole lamp can be achieved by chouse the different resistance schemes.

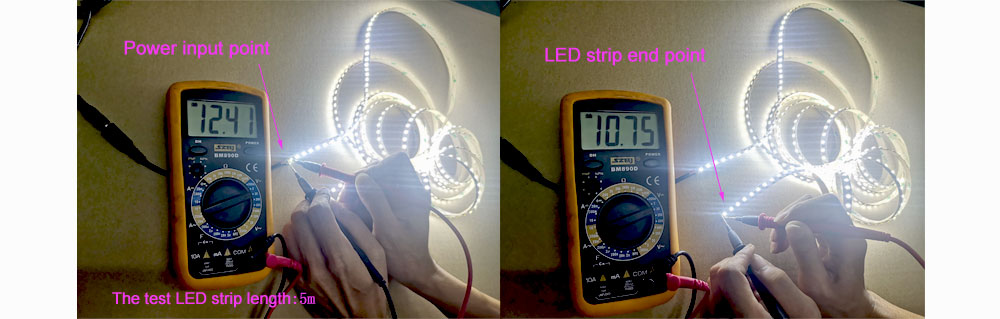

3. The influence of the length of the light strip on the brightness

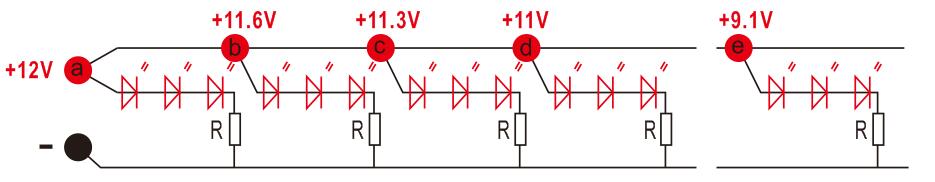

Constant voltage led strip, when the length of the light strip is greater than 5m, the voltage drop on the strip will be more obvious, then the voltage of the first LED position and end LED position of the led strip light will be inconsistent, the tail voltage will be lower than the voltage of the first LED.

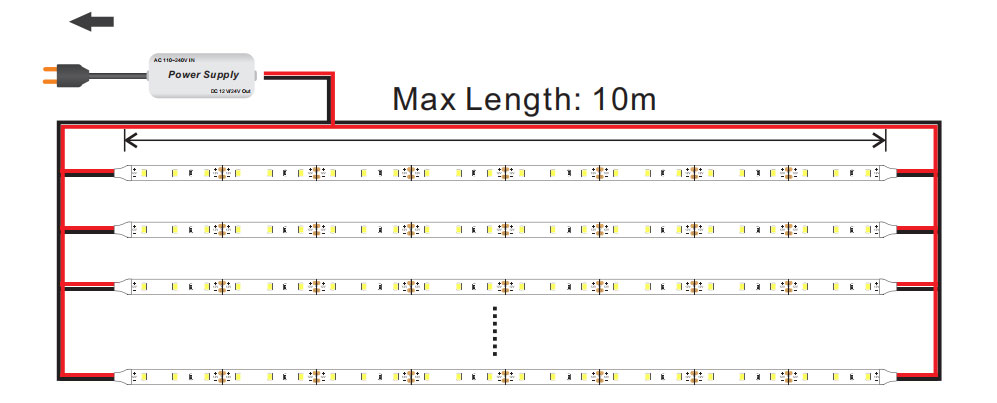

As shown in the figure below, the power voltage is 12.4V, and the tail voltage has dropped to 10.7V, which will cause the problem of inconsistent brightness at the total of the light strip.

Therefore, when the length of the light strip is greater than 5m, this problem can be solved by supplying power at both ends, as shown in the following figure.

4. The effect of working voltage on the brightness

Constant voltage light strips, the same number of LEDs, the same circuit scheme, using the same LED Chips, using the same resistance, if the length of the led strip is longer, the 24V led strip is brighter than the 12V led strip. This because of the higher the voltage, the smaller the voltage drop, as shown in the figure below.

The voltage at the end of the 24V led strip is 22V, and the voltage applied to each LED is 2.8V, while the voltage at the end of the 12V LED strip is 10V, and the voltage applied to each LED is 2.5V. You should know that the rated Vf value of the LED is 3V, obviously, 2.8V is closer to the 3.0V rated Vf value, so the brighter the light strip.

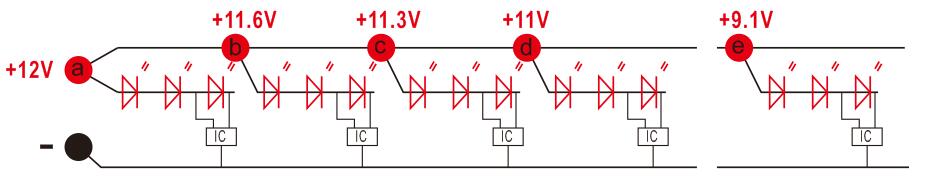

5. Influence of constant current IC chip on the brightness

Due to the internal resistance of the PCB board of the light strip, the constant current led strip also has a voltage drop, but the circuit scheme used by the constant current strip is different from that of the constant voltage light strip.

The figure below shows the circuit schematic diagram of the constant voltage led strip.

The figure below shows the schematic diagram of the constant current led strip.

There is one IC chip in each group of LEDs in the constant current Light strip. The LED will be connected in parallel with an IC chip, and to dynamically adjust the voltage applied to it. So that the LEDs of the entire group work at the rated voltage. This will keep the consistent brightness of the entire LED strip.

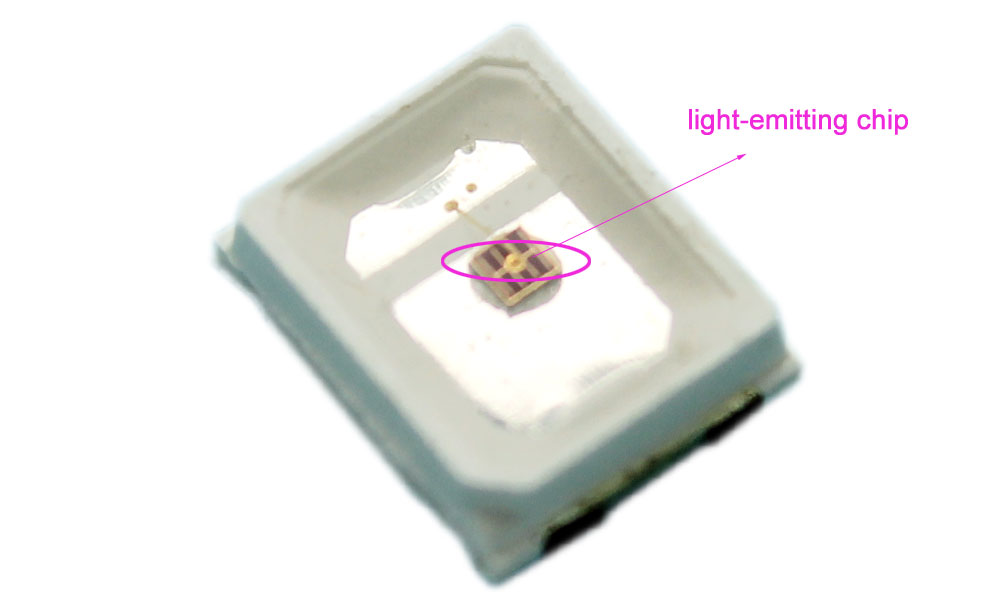

6. The effect of light-emitting chip size on the brightness

a. The same type of lamp beads has different sizes of LED light-emitting chips, this will resulting in different LED brightness.

The difference between high-brightness and normal-brightness of the LED is caused by the different sizes of the light-emit chip used in the LED.

For example, the 5050 LED has 18-20lm, 20-22lm, 22-24lm, 24-26lm, and so on.

b. Different LED types have different brightness.

For example, the brightness of a single LED of 5050 or 2835 is basically around 20-24lm, while the brightness of 5630 LED can reach 45-55lm. This because the led chip used by 5630 LED is bigger than the chip used by other LEDs.

Of course, compared with other models of the same LED type, the larger the chip, the higher the brightness and the higher the price.

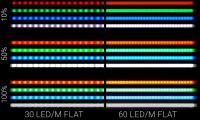

7. The effect of lamp bead density on the brightness

Use the same type of LED, if the brightness is not enough, you can increase the brightness by increasing the density of the LEDs.

For example, the led strip type of the 3528-120 LEDs/m will be much brighter than the type of the 3528-60 LEDs/m, and 5050-30 LEDs/m will be much darker than 5050-60 LEDs/m.

5. The LED density and power consumption of LED Strip Lights

We know that with the same type of LED, increasing the number of LEDs per meter can increase the brightness of the led strip light. Of course, this also increases the power of the light strip.

Therefore, the greater the density of LED strips with the same circuit structure, the greater the power.

Normally, led strip lights’s LED number is 30leds / m, 60leds / m, 90leds / m, 120leds / m, 240leds / m.

So, is it that the greater the power, the brighter the light strip?

A key parameter needs to be introduced here: Light efficiency.

Light efficiency is a parameter that characterizes the photoelectric conversion efficiency of a lamp. It refers to the brightness of led light that can be emitted per watt of power. The unit is lm / w. The larger the value, the higher the photoelectric conversion efficiency, and the more energy-efficient it is.

For example, there are two factories that produce the same 2835-120leds/m led light strip. We mark the light strip produced in factory one as the No. 1 light strip, and the second plant marked as the No. 2 light strip.

The No. 1 light strip↓

The No. 2 light strip↓

Through the integrating sphere test report, we can see that the brightness of the No.1 is better than the No.2 light strips, but the power of the No.1 light strip is 9.22w, it’s low more than the No.2. What happened?

The No. 2 light strip is much power than the No. 1 light strip, so it consumes more energy. As can be seen from the test report, the light effect of the No. 2 light strip is 92.43lm / w, and the No. 1 light strip is 141.01lm / w.

Therefore, it is unreasonable to judge the brightness of the light strip simply from the power level, and we must pay attention to the Light efficiency of the light strip, so as to achieve the purpose of using led lights to save energy.

6. The color temperature of the led strip light

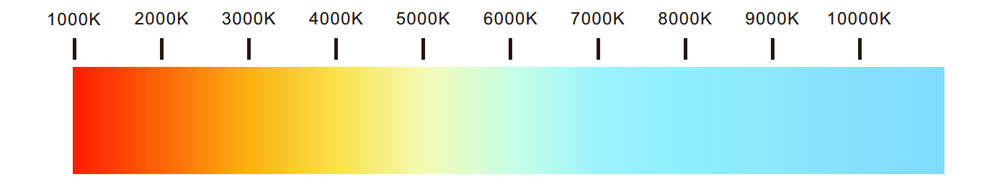

1. Common colors have these: warm white light, the color temperature range is about 2100K-3000K. Natural white, the color temperature range is about 4000-5000K; positive white light (the color of noon sunlight), the color temperature range is about 5000K-6000K, cold white light, the color will close to blue, and the color temperature is above 6000K.

Because the color temperature corresponding to the above terms is an interval, the span of this interval is relatively large. If the led strip factory produces the light strip according to this standard, the led strip light color will be seriously inconsistent.

Therefore, an international strict regulation that the color temperature of a qualified light source must be controlled within 7 steps.

The Color Tolerance of LED Strip Lights – This article introduces in detail all the knowledge about the color tolerance of LED lights.

Usually, when we buy a light strip, we will not only tell the supplier that I want white or warm white light strips but also explain that the white color temperature is 4000K and the warm white temperature is 3000K. So that let the factory understand what led strip lights you need.

2. Choice the color temperature

Generally speaking, people in an environment with a high color temperature above 5000K are more likely to be excited, concentrate, engaged in delicate work, and also more prone to fatigue.

3000K low color temperature will be more relaxed and more secure, while moderate natural light with a color temperature of around 4000K can better reflect the color of the object itself.

So choosing which color temperature light we use depends not only on personal preference but also on the layout of the user environment.

7. The power classification of led strip lights

1. Power supply for low-voltage strip lights

According to the appearance characteristics, the power supply mainly divided into three types: desktop power supply, aluminum shell power supply, and waterproof power supply.

The desktop power supply is very similar to the laptop’s external power supply, the only difference is the output voltage.

The aluminum shell power supply has more DC output terminals, which can connect more led strips in parallel to facilitate wiring. It is mainly used in permanently fixed and centralized power supply places.

The waterproof power supply is mainly used in a rainy or humid environment.

2. Power supply for high-voltage led strip lights

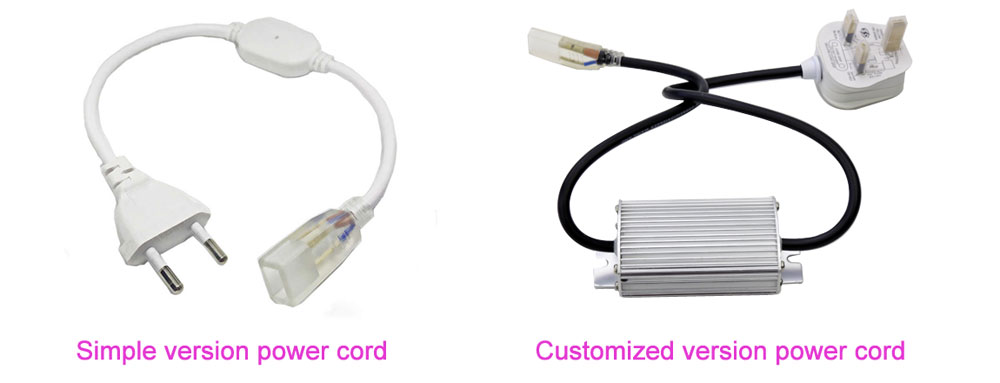

There are two types of power cords for the high-voltage light strips: the simple version and the customized version.

Before leaving the factory, there will be equipped with a simple version power cord to every led strip light.

After the user gets the strip lights, plug the power cord directly into the AC socket and the light will be working Light up.

The customized version power cord will be better than the simple version, and there will be no stroboscopic problems with the lighted light strip.

10 Differences Between 110V-240V LED Strip Light And 12V/24V LED Strip Light – Read this article to learn more about led strip lights with strobe.

8. Dimming and color control of LED strip lights

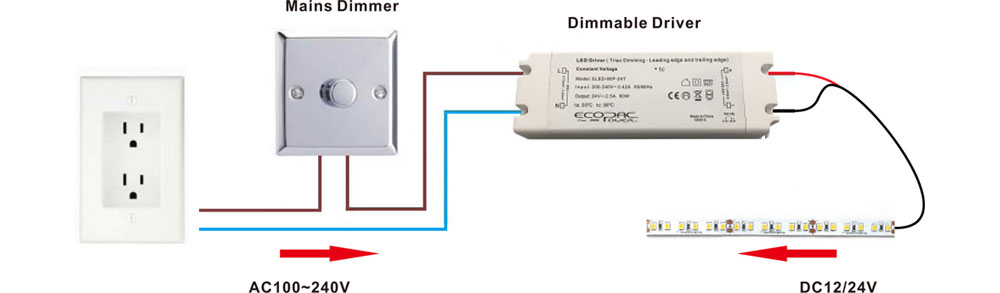

All low-voltage monochromatic light strips support dimming. There are two main dimming methods for the light strips: dimmable power supply dimming and low-voltage dimmer dimming.

Dimmable power supply dimming requires the use of AC wall control dimmer and dimmable power supply.

The main dimming methods of dimmable power supply are TRIAC Dimming / DALI Dimming / 0 / 1-10V Dimming / ZigBee Dimming.

The wiring diagram is as follows

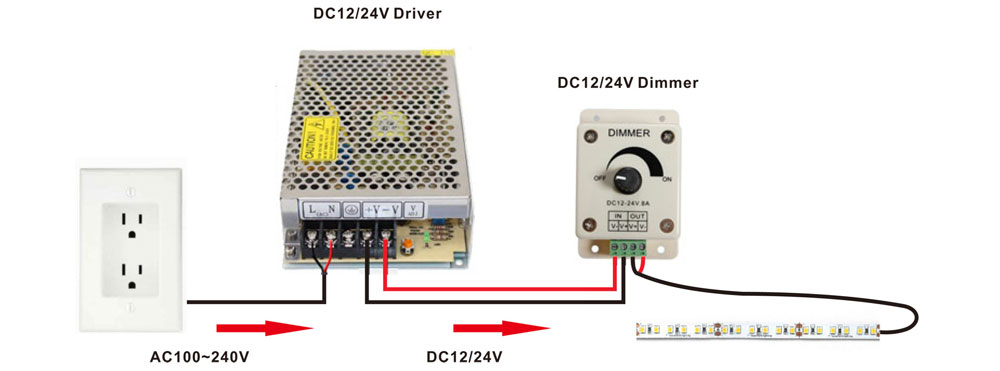

For low-voltage dimmer dimming, a DC dimmer is needed. The dimmer needs DC12V or DC24V power supply, and then connect the positive and negative poles of the led strip to the positive and negative poles of the dimmer output end.

The wiring diagram is as follows

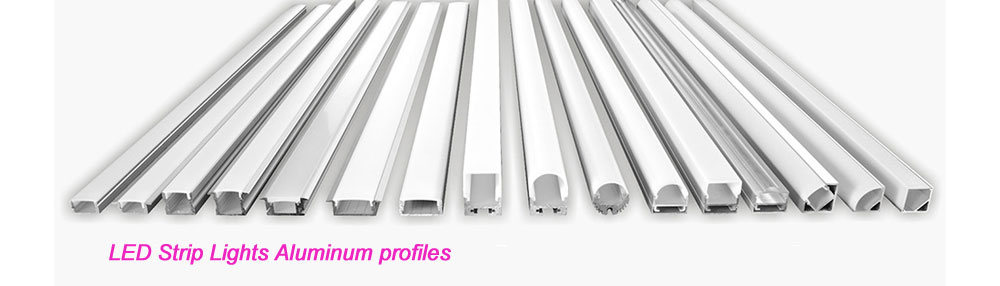

9. The heats dissipation device of the LED strip light

Aluminum profiles, as accessories for led strips, have pushed linear lighting applications to a new level.

The application of led strips is no longer limited to the field of auxiliary lighting or decorative lighting. More main lighting products are coming one after another.

For example, the following main lighting products have been widely praised by customers once they are put on the market. The emergence of aluminum grooves makes LED light strips more popular in the field of linear lighting.

Almost any lighting scene has LED strip lights.

Clothes rails, stairs, baseboards, cabinets, underground lights, etc. In these places, if you want to make straight shine lines, led aluminum profiles are indispensable.

In addition, some of the inherent characteristics of the aluminum profile, such as easy installation, beautiful appearance, and good heat dissipation, are also deeply loved by users, making it a hot product in people.

10. Waterproof technology of led light strip

There are four main waterproof levels of led light strips, which basically meet the waterproof requirements of various application scenarios.

1. Drop glue waterproof: it is to drop a layer of glue on the surface of the bare board led light strip. This layer of glue can be silicone, epoxy, or PU glue.

What Is The Best Glue For LED Strip – This article explains how to choose the right waterproof glue for the light strip.

The waterproof level use this process can make led strip to reach IP54, but many factories will call this kind of light strip as the IP65 light strip, which is actually not up to the waterproof level of IP65.

2. Wear silicone casing waterproof: The bare board light strip is sealed with a silicone sleeve, and the two sides of the sleeve are sealed with a silicone plug through the form of glue. The waterproof level of this process can reach IP65.

![]()

3. Nano-waterproof: A nano-coating film is formed on the surface of the bare strip. The formed film is integrated, which can prevent water molecules from contacting the electronic components of the led strip. This waterproof performance can reach the IP65 level.

4. Silicone Extrusion Waterproof: The bare board light strip is passed through a high-temperature silicone extruder, and the silicone and the light strip are die-casted into one body.

Then the silicon waterproof power wire connector will be die-cast at the end of the light strip. The waterproof level of this process can reach IP67.

![]()

5. TPU integrated molding technology: the bare board light strip and the liquid TPU compound are cured together, and there are no plugs on both sides of the light strip, no secondary process intervention so that the waterproof performance of the light strip reaches IP68 level, and there is no problem when used underwater.

11. Connection method of the led light strip

1. The connection between two led strip lights

The led light strips can be arbitrarily cut, so you need a flexible connection method to connect the light strips. The most common way to connect led light strips is to connect them with snap connectors.

Of course, this connection method also has its limitations, that is, for the waterproof led strip, after the second docking, there will no longer be the same waterproof level as the originally led strip.

Therefore, for the waterproof led strip light, if the installation environment must have such a high waterproof level, don’t cut it to use it. You can directly ask the supplier to customize the waterproof light strip that you need length. This should be the best solution for you.

2. The connection between the led light strip and the power supply

Usually, the led strip power wire is a single color stripe with red and black wire or a DC female connector at the end.

The red and black wires are used to facilitate the connection of the power supply with terminal blocks like the aluminum power supply. The DC connector is convenient to connect with a DC male connector similar to a desktop power supply.

Two-color light strips and CCT light strips will have 3 wire lines at the end to facilitate connection to the controller terminals of the two-color light strips.

RGB light strip, the end will have an RGB wire or RGB-4PIN header, which is convenient for a fast connection to the RGB controller.

12. How to install the led strip light

1. Indoor installation: Usually before leave factory, bare board non-waterproof light strip, epoxy covered waterproof light strip, and silicone tube light strip, the back of the light strip will be equipped with 3M adhesive.

When installing, only need to tear off the adhesive release paper, And then paste the light strip to the appropriate position.

Of course, all light strips can be fixed with silicone clips. Epoxy light strip or tube light strip, because the main body of the light strip is relatively heavy, so you would be better to use the clips to fix it, as shown in the figure.

2. Outdoor installation: If it is installed outdoors where it will not be soaked by rainwater, you can use an IP65 tube light belt. It is mainly fixed by snaps or slots.

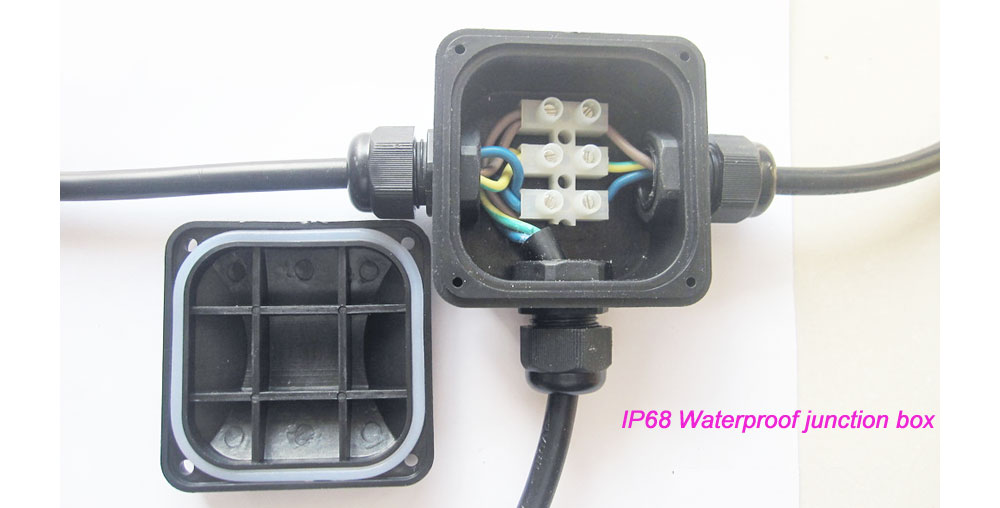

If it is a swimming pool or a small ship, it is recommended to use IP67 or IP68 waterproof light strips. The fixing method is mainly a buckle or a card slot. At the same time, do the waterproof treatment at the power supply connector. It is recommended to use a waterproof junction box as shown in the figure.

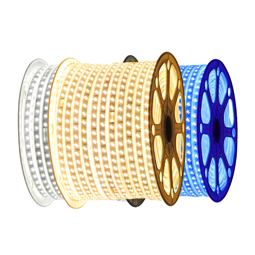

13. Conventional packaging methods for led light strips

The most common packaging method for light strips is reel + anti-static bag packaging

1. There are mainly two types of anti-static bags, silver and transparent. Different sizes of bags are selected according to different reel sizes.

2. There are mainly two types of reels: plastic reels and paper reels. The colors of the reels are mainly black and white. Choose reels of different sizes according to the size of different light strips.

3. Labels, each bag needs to be affixed with a corresponding label to indicate the specifications of the light strip.

4. Desiccant, if the light strip is left for too long without lighting, if the storage environment humidity is relatively high, the led light strip is easily damp, so each roll of the light strip will be equipped with a desiccant in the packaging bag. Of course, it is best to install and use the purchased light strips in time, and do not leave them for too long. Prevent the lamp beads from aging and damp, affecting the service life.

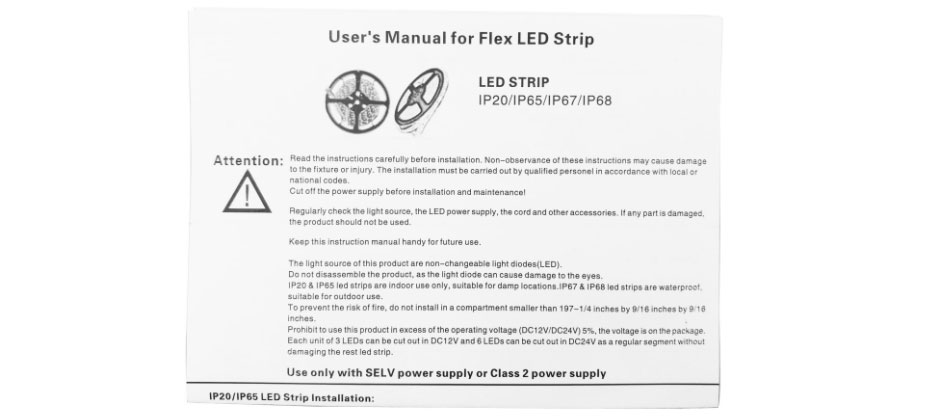

5. Instruction, the regularly led light strip manufacturer will provide the light strip instruction manual in each packaging bag, which will indicate the use of the light strip and the precautions for use.

6. Accessories, if you buy IP65 or IP67, IP68 waterproof light strips, there will be corresponding buckle and plug accessories in each bag, as shown in the figure below.

14. Customization of light strips

LED Light strip, as a very popular lighting product, in order to meet people’s differentiated lighting needs, of course, some special customization is indispensable.

The light strip is not only just thin but also very long.

The width of the PCB board of the light strip, board thickness, board circuit structure, board appearance, board color, board logo printing, etc. can be freely designed and customized.

The electrical parameters of the led strip light, such as power, brightness, color temperature, CRI, etc., can be adjusted and customized freely by the factory.

The density of the lamp beads, the lamp bead model, the size of the lamp beads, the selection of the led chip brand of the lamp beads, etc. can all be customized.

The control change effect of the light strip, special scene application, special function, and so on can all be customized.

1. If you can design the appearance of the light strip and the light strip circuit, you only need to send the designed drawings to the cooperating supplier, and then after the factory confirms that it is correct, next will can make the board and produce the product.

2. If you have your own ideas, you only need to give the scene lighting effect you want to achieve, and the supplier will provide you with a plan. After adopting it, next will make the board directly and produce the product

3. About logo customization, you only need to provide the logo image to the supplier.

4. For the Certification listing, if you want a UL certification number of your own company, but you don’t want to spend too much money to do repeated certification yourself, then you first find a supplier with UL certification, and then To cooperate with the supplier, you only need to provide some documents, and then the supplier will reach a listing agreement with UL to generate a new UL certification number for you. In this way, only a small part of the fee needs to be charged.

15. Precautions for the use of led light strips

1. Please use 24VDC isolated power supply to drive the led strip, and the constant voltage source ripple less than 5%. Can’t step-down the power by resistance- capacitance and nonisolated power supply driver led strip, etc.

2. To ensure the longevity and reliability of the strips, please do not bend the arc diameter 60mm or less, do not fold to avoid damaging the lamp beads or broken.

3. To ensure the life and environment of lights, in the use of force can not pull the power cord to avoid damage to prohibit collision LED lights.

4. During the installa1on of posi1ve and nega1ve aFen1on to the power cord, do not pick the wrong voltage power supply and the product is the same, so as to avoid damage to the product.

5. LED lights should be stored in a dry sealed environment, the proposed storage period should not be too long before using unpacking, the working temperature: –

20℃ ~ + 45℃ ,Storage temperature: -0℃ ~ + 60℃, not waterproof lights band indoor use, rela1ve humidity not higher than 70%.

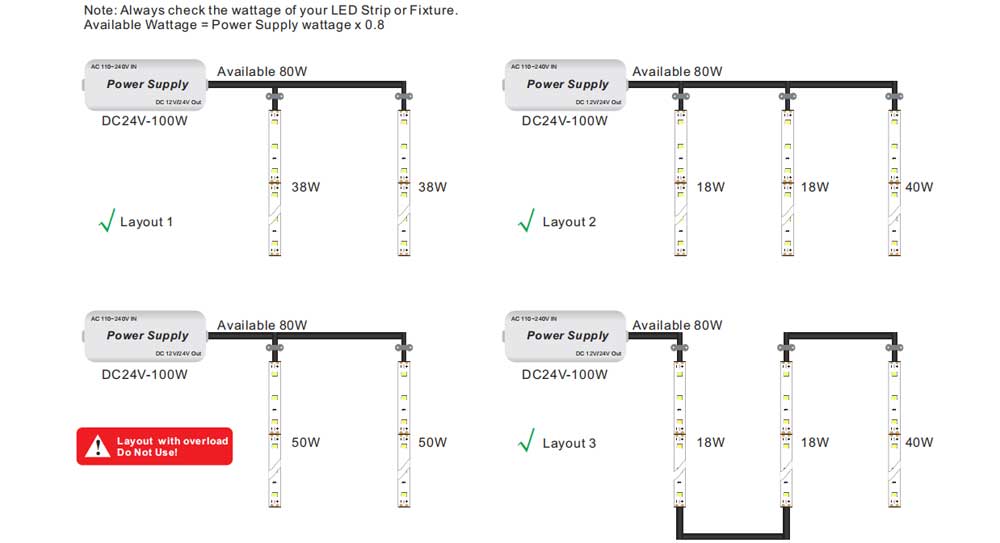

6. In prac1cal applica1ons, the power supply should leave 20% margin (recommend using only 80% of the power) in order to ensure a sufficient amount of voltage

drive products

7. Do not use any acidic, alkaline adhesive securement products (including not limited to glass, plas1c, etc.)

8. When the led light strip is rolled into a roll, piled up in a ball, or has not been separated from the packaging, please don’t light up the light strip for a long time.

9. Only cut the light strip at the place where the mark is printed on the body of the led light strip (cutting a whole cut unit), otherwise, the light strip will not light up for the whole cut unit row.

10. When installing the led light strip, cut it clean with scissors without leaving burrs to avoid Short circuit fault.

11. Do not turn on the power during installation or assembling of the light strip. The power can only be turned on when the connection and installation are good.

12. In the process of installation and use, please don’t knock the light strip with a blunt object, and don’t press the light strip with a heavy object and shake it.

13. The tail end of the led light strip must be covered with a tail plug and glued with glass glued or fastened with adhesive tape. It must be protected from water in outdoor use.

14. Only two light strips with the same specification and power supply can be connected to each other, and the total length of the connection cannot exceed the maximum allowable length

15. For installation and fixation, please don’t use metal materials wire to tie the led strip light, so as to avoid the iron wire from falling into the lamp belt, causing leakage current, short circuit fault and burning the strip light.

16. The power supply’s power should be large than the voltage marked on the led light strip and should be installed in a safe place.

17. During the use of the led strips, please do not wrap or cover the strips with any objects to ensure good heat dissipation.

18. This product is not a children’s toy, but it is easy to arouse children’s interest. Please install it in a place where children cannot touch or use it under supervision.

16. LED strip troubleshooting

| No. | Fault phenomenon | Possible reasons | Solutions |

| 1 | All LEDs dark or discoloration | No power supply from the driver | Power delivery |

| Strip with reverse polarity | Correct wiring | ||

| External power supply bus short circuit, switching power supply automatic short circuit protection | Excluding short-circuit fault, re-transmission | ||

| Power fuse burned | Replace fuse | ||

| 2 | Parts led units dark or discoloration | No power supply from parts of the driver | Check the power supply system, troubleshoo1ng |

| Part of the light string supply line error | Check the power supply circuit, troubleshooting | ||

| 3 | Uneven lumen output or short brightness | Overload power | Add power |

| Switching power line lossy | Bold power wires, or adjust the power supply position(the distance light with closer position)Make sure the line voltage into the lamp every five meters in 95% of the rated voltage of the above | ||

| An excessive number of light strings connected | Adjusting the quantity of each supply branch of the lamp, Meet the requirements of each power supply circuit with the largest lamp | ||

| 4 | LED flicker | Bad wiring contacts | Find the bad element point, troubleshooting |

| 5 | Individual LED dark | Electrostatic breakdown | Discover the associated electrical and well grounded, replace the SMD. |

| Induction equipment breakdown (or leakage) | Discover the associated electrical and well grounded, replace the SMD. |