LED Neon Flex Tube Silica Gel Flexible LED Strip Light Tube IP67 Waterproof for Decoration

Silicone Neon LED Strip Tube, as a kind of protective material to led strip, fabricated by the integrated silicone extrusion molding technology with ingress protection up to IP67 and good performance of resistance to salt water, chemicals, UV radiation, and fire.

![]()

Which can be widely used for indoor & outdoor stylish design, like roof corners, corridors & edges, and other places for decorative lighting.

Product introduction

Silicone led strip diffuser is a new bendable silicone led channel and is used for led strip lights lighting.

It is made of food-grade silicone material, environmentally friendly, odorless, long-term use will not turn yellow, can be arbitrarily bent, and flexible.

Waterproof to IP67, it can be used anywhere which is dry, wet, or splashed with water.

Because of its soft material, this silicone led profile can be cut according to any size, so as to meet the length requirements of different scenes, different ideas, and different artistic effects.

The flexible silicone LED channel system (integrated) is an excellent alternative to traditional LED aluminum channel profiles.

It has a more beautiful appearance, as well as a softer diffuse effect, making the decorative effect more atmospheric, and more tasteful.

Physicochemical properties

Resistant against water, chemicals, UV radiation, and abrasion.

Non-toxic environmental protection, food-grade silica just like a baby pacifier.

Fire-protection rating V1.

Silica molecular structure stability ensures the coating is yellowing resistant and has no changes for many years.

Wide range of use

It is fully capable of under-cabinet and back-splash lighting, accent lighting, and decorative lighting.

LED silicone tube systems can be widely used in kitchens, wardrobes, bathrooms, bedrooms, living rooms, closets, courtyards, bars, movie theaters, shops, parties, display windows, supermarkets, etc.

Meet the needs of most lighting projects.

The IP67 waterproof rating makes it an excellent lighting choice for both indoors and outdoors.

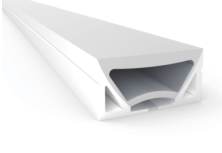

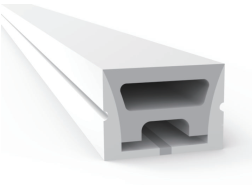

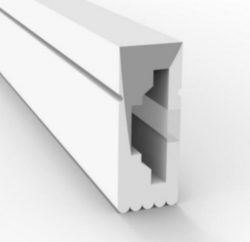

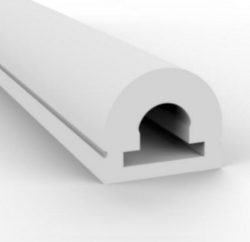

Product categories

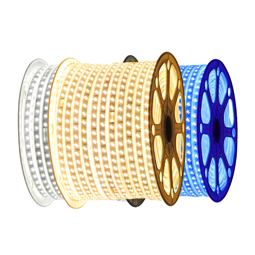

led strip silicone tubes to come in a wide variety of sizes and appearances to meet the needs of different application scenarios.

According to the luminous surface orientation, it can be divided into side-view, top-view, 270-degree, 360-degree views.

![]()

The neon flex tube has three color types: transparent, milky white, and black.

The inner diameter of the led neon tube has a very large number of sizes, which are used for various led strips with a width of 3/4/5/6/8/10/12/14/15/20/28mm.

The width of the led strip applicable to each casing will be found in the corresponding led silicone tube specific parameters.

Silicone led strip diffusers are usually packed in a 100 m (328 ft)/roll, but you can also ask to be cut to a specific length, such as a 16.4 ft/roll, to pack.

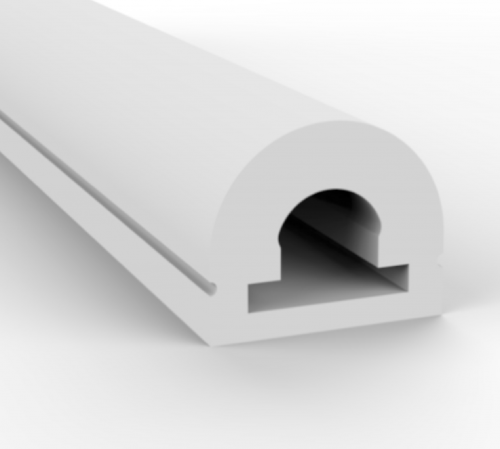

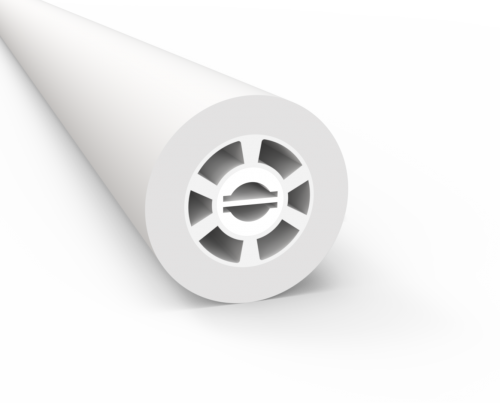

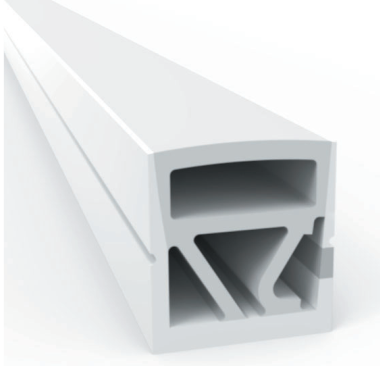

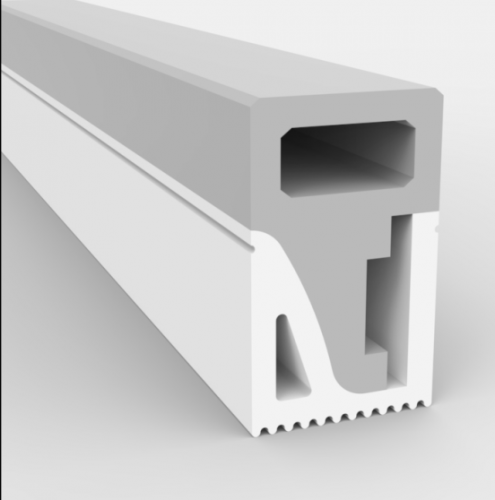

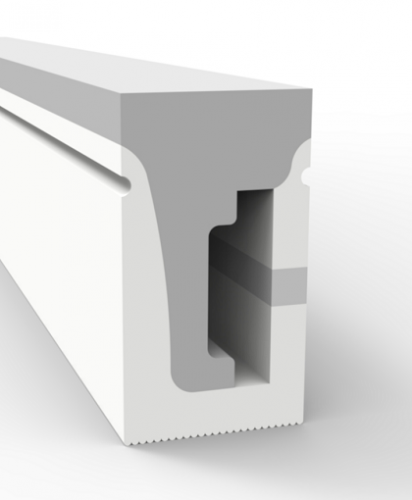

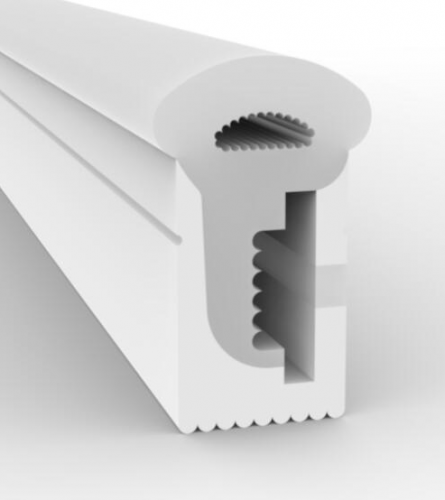

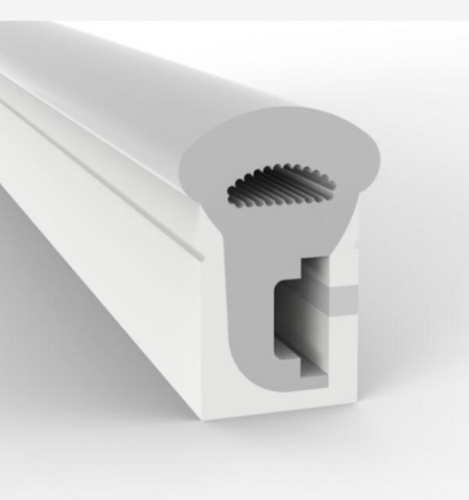

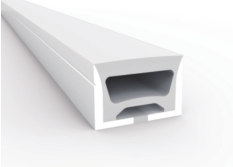

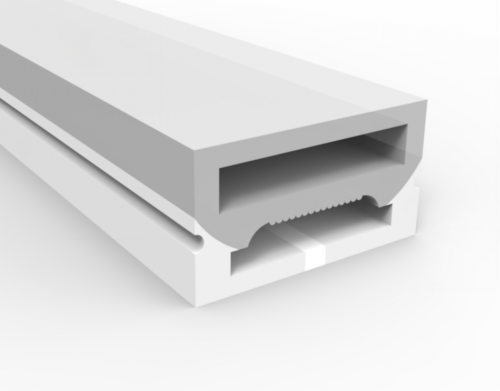

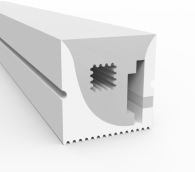

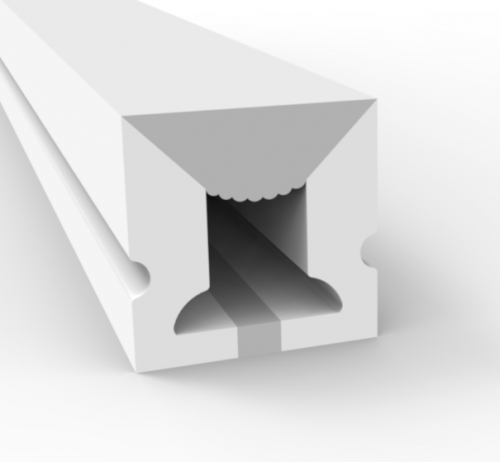

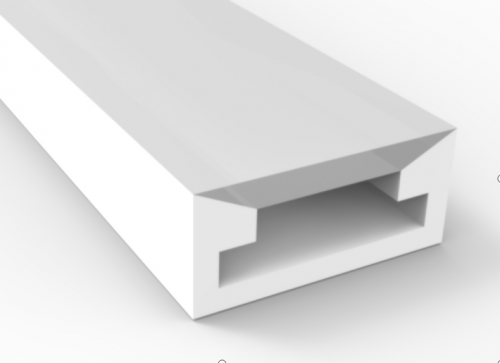

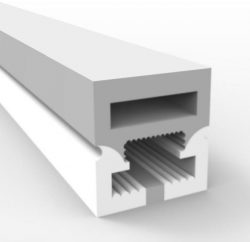

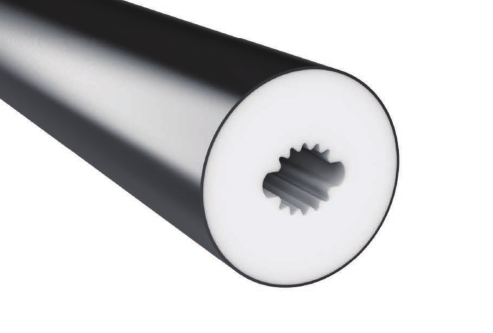

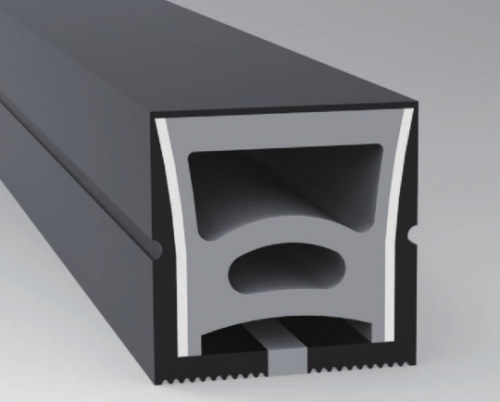

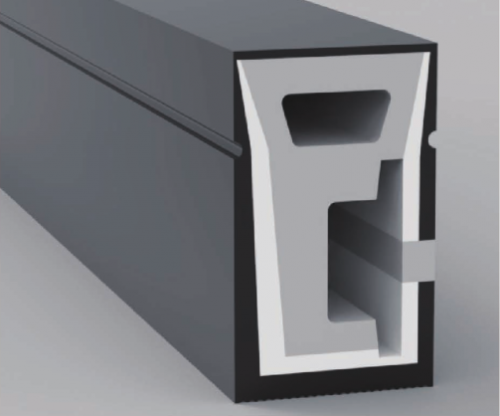

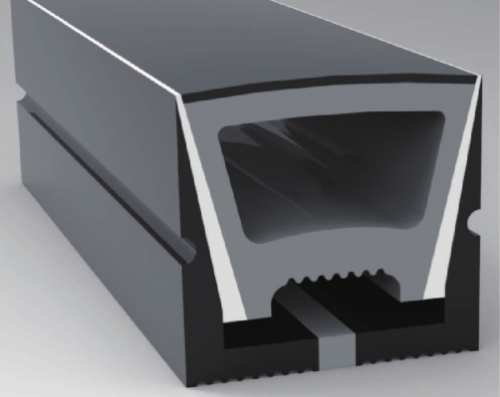

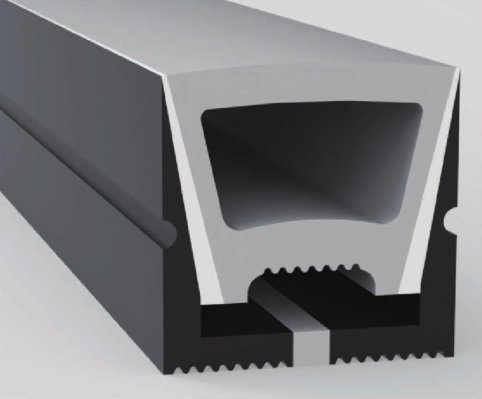

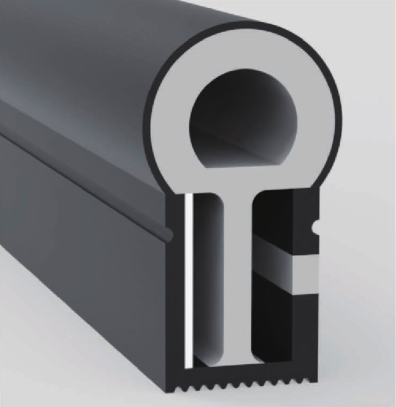

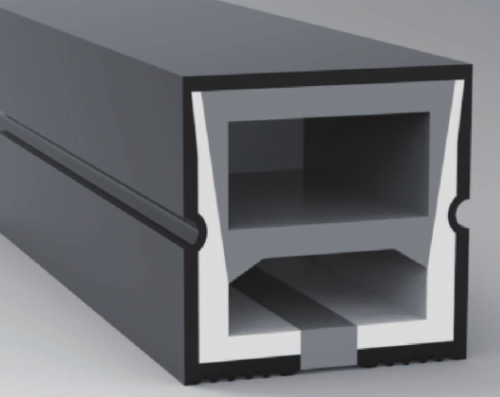

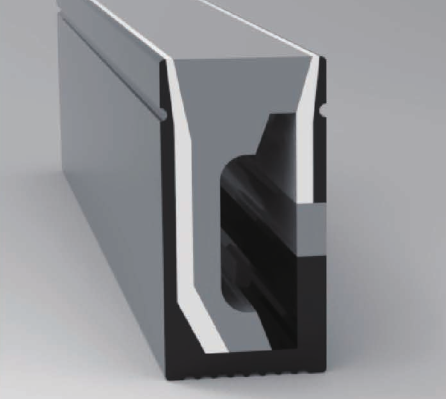

Structure of led strip silicone tube

The silicone tube consists of 6 parts:

The main silicone tube body, the luminous body, the traction groove (led strip groove), the traction rope, the light strip window, and the anti-breaking plate.

1. As shown in the figure below, where the emitter is the main luminous part of the silicone led diffuser. The shape and orientation of the luminous body determine the beam angle of illumination of the neon strip light and the direction of the light.

![]()

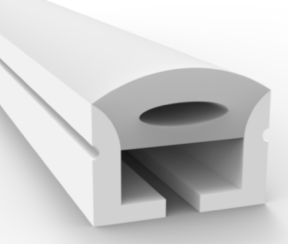

2. The main silicone tube body is used to prevent light from spilling out from other directions and as the main supporting component of the tube light body.

3. The traction slot is also called the light strip slot and is used to accommodate the LED strip light.

4. The tow rope is made of pure cotton thread with high strength and high toughness, which can withstand very large pulling forces. Its role is to tow the led light strip into the silicone tube.

5. A light strip window is a viewport used to view led strip crop lines. Through the viewport, you can clearly see the cutting marks of the light strip in the sleeve, which is convenient for the cutting and installation of the neon led strip.

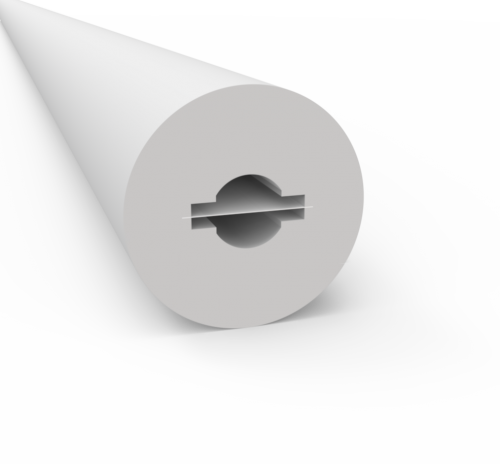

6. The anti-breaker is made of high-strength and high-toughness PC.

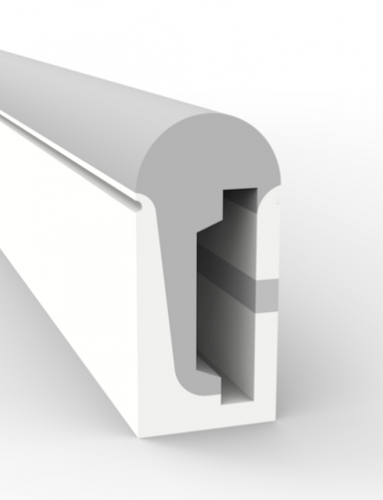

![]()

It does two things:

a. One is to provide greater strength and toughness for the silicone neon tube.

Because the led neon tube itself is made of silicone, the silicone body is easily stretched, and the silicone led channel is relatively thick, which is easy to be stretched and broken in the case of a relatively long silicone tube.

In order to prevent this from happening, high-quality silicone led strip diffuser will be equipped with anti-break plates in the silicone body to improve the strength and toughness of the silicone led channel.

b. The second effect is to reduce the friction when pulling into the strip.

When pulling the led strip into the silicone tube, if the length of the silicone tube is relatively long, then the friction between the inner wall of the casing and the strip is very large, it is more difficult to operate, and it is almost impossible to complete if the air compressor is not used to blow the air.

After adding the PC anti-breaking plate, the PC board is very smooth, compared to the silicone inner wall, this friction will be reduced a lot, even without the help of an air compressor blower, it is easy to pull the led strip into the silicone led channel.

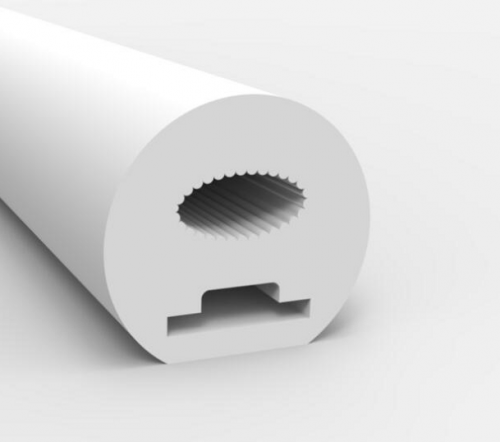

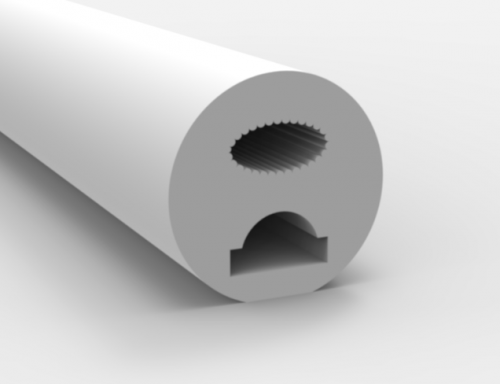

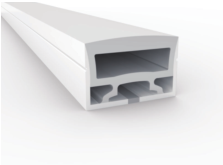

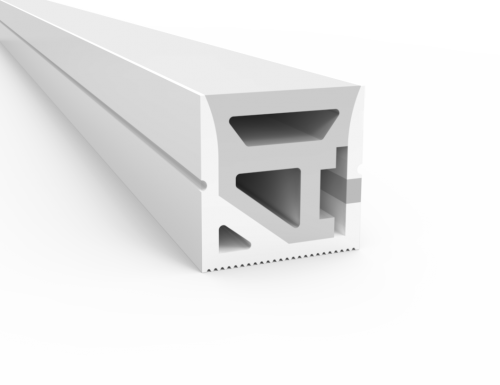

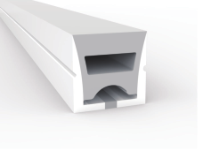

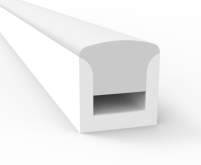

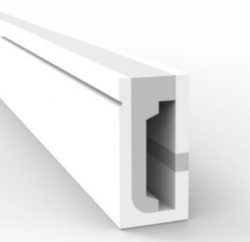

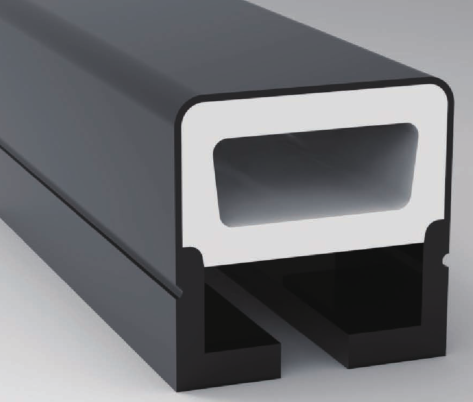

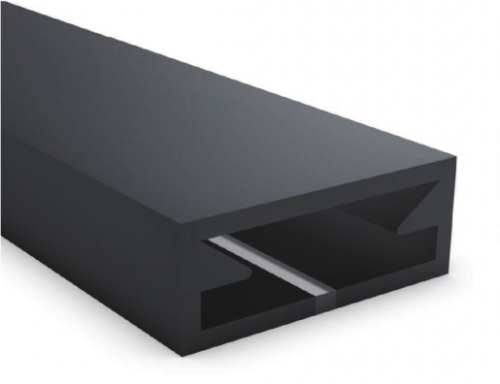

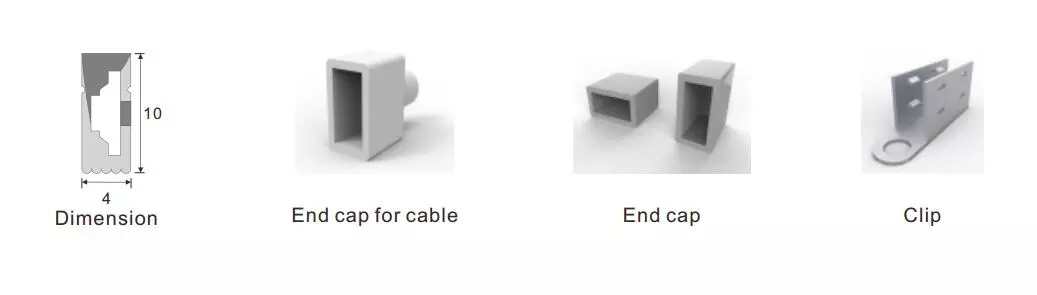

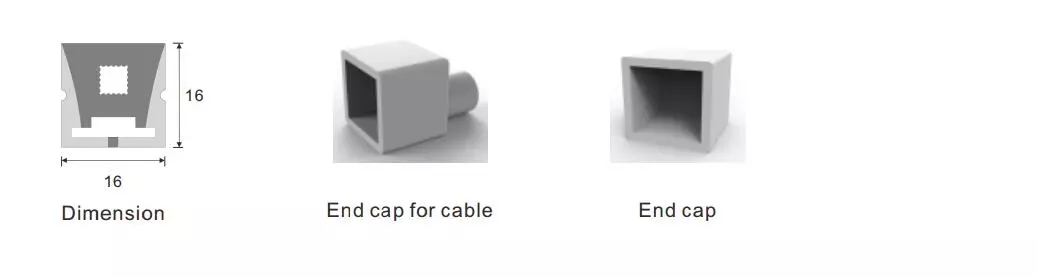

The way silicone led diffusers are named

Almost all products on the market are named according to the size of the width and height of the silicone led profile.

For example, in the 0410 silicone tube, the first two numbers 04, represent the width of the sleeve is 4mm. The last two digits 10 indicate that the height of the casing is 10mm.

![]()

This way, you can quickly know the approximate size of each led strip silicone tube.

If your usage scenario requires a striplight led tube with a width of about 16mm, then you will definitely need to find a suitable product in the led silicone tube that starts with 16 to meet your requirements.

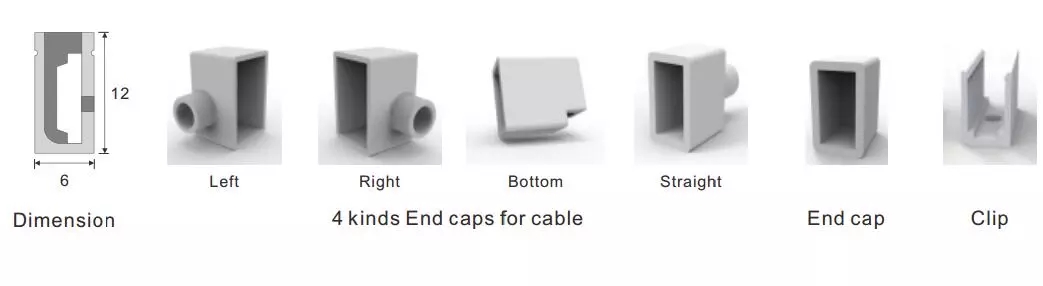

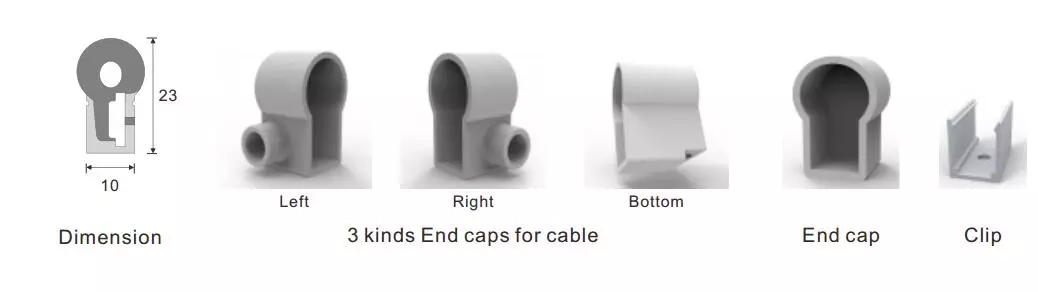

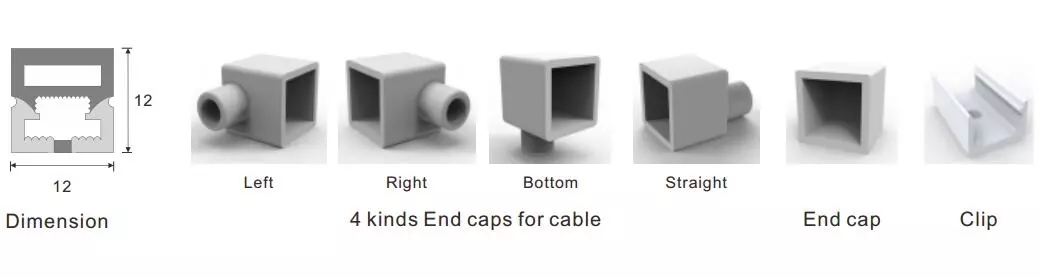

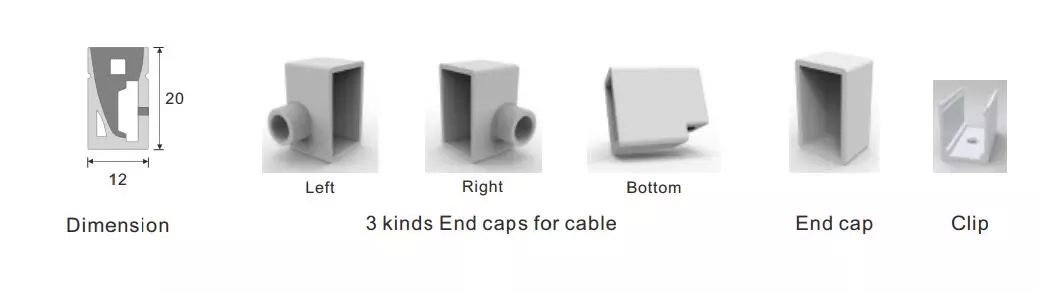

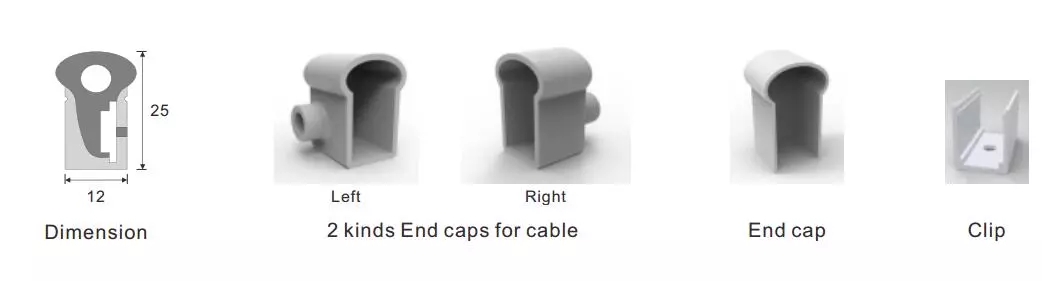

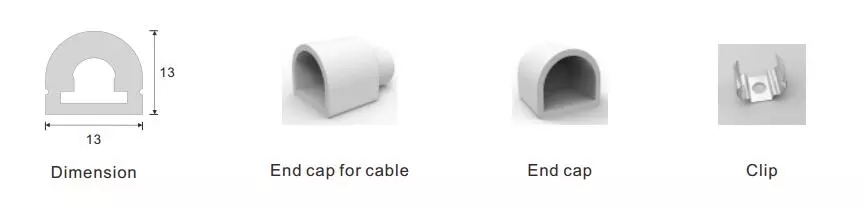

The way the silicone led channel is routed

Because different use cases will have different wiring methods, in order to facilitate the power supply of silicone neon tubes, each casing will be equipped with a different direction of the plug, some are left out of the line, some are the right line, some are straight out, and some are bottom out.

![]()

This provides great convenience for the installation of led neon strips.

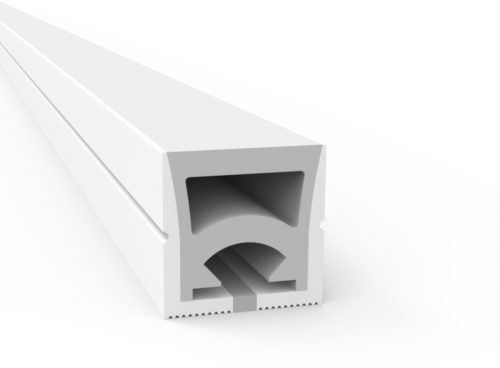

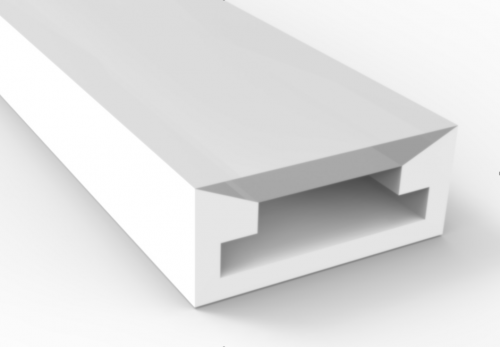

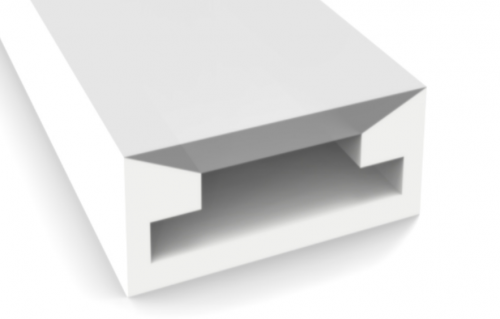

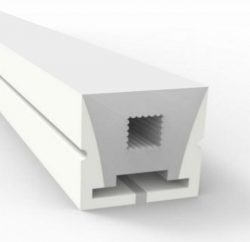

The way the led strip light tube is mounted

1. The most common way to install a silicone led channel is snap-on mounting. Each silicone tube has the snap to fit its own size.

![]()

2. The second way is the card slot installation. The card slot material is usually made of aluminum, as shown below.

![]()

3. There is also a 3M adhesive backing installation. The 3M adhesive mounting method is only suitable for some smaller silicone led profiles. And 3M tape needs to use VHB tape with strong adhesion, ordinary tape is not OK. In addition, before the tape is glued to the silicone channel, the casing must be applied with a silicone treatment agent, otherwise, the 3M adhesive will not be able to bond firmly with the casing.

![]()

Product Features:

1. Wide applicability, easy to install and maintain;

2. Extremely luminous, with a wide viewing angle;

3. Unique waterproof technique;

4. Environmental conservation, long lifespan;

5. 3 Years Warranty.

Product Description:

0410 bendable silicone led strip diffuser

Suitable PCB Width: 6mm

0612 bendable silicone led strip diffuser

Suitable PCB Width: 8mm

1023 bendable silicone led channel

Suitable PCB Width: 10mm

1212 Silicone Neon Flex Tube

Suitable PCB Width: 8mm

1220 led strip silicone tube

Suitable PCB Width: 10mm

1225 led strip silicone tube

Suitable PCB Width: 10/12mm

1313 led strip silicone tube

Suitable PCB Width: 8mm

1616 silicone led strip diffuser

Suitable PCB Width: 10/12mm

HOW TO USE silicone led strip channel

Note: Each silicone LED channel has a white cotton thread inside it, which is used to pull the LED light strip into the silicone tube. The line is the same length as the silicone casing!

How to insert LED strip Light into the led silicone tube? (wear the casing)?

Before wearing the casing, we need to confirm the length of the two belts, the length of the led strip we used, and the length of the silicone led channel.

Since the length of the led strip is determined by the minimum length that can be cut by itself.

Before the light strip is cut, it is necessary to compare the strip with the light strip at the place where it needs to be installed, and then find the top of the strip according to the actual situation.

The scissors hole is cut off, this is the length of the light bar, and then the silicone tube with the same length as the light strip can be cut.

Something you need to use during the operation is:

![]()

Step 1

Tie the traction line of the neon flex strip inside the flex silicone tube to the line of the led strip light.

![]()

Note: the line must be tied firmly to avoid falling off.

Step 2

The beaded side of the led light strip corresponds to the side of the lamp bead inside the silicone led diffuser bushing that is stuck in the slot.

![]()

Step 3

Then lay the led strip and the silicone led channel bushing flat, and start to pull the led strip light slowly from the other side of the bushing until the led strip is pulled to the other side of the silicone tube bushing.

![]()

Note: if the length of the silicone tube used is less than or equal to one meter, the led light strip can be passed directly without the need to tie the traction line.

Step 4

Light up a test to see if the led flex tube works properly. If there is any problem, you can directly pull out the light strip, repair or replace it, and re-put it in.

Step 5

Run the neon plug over the light line and then push the silicone into the plug slot.

![]()

Step 6

Insert the plug at the end of the neon flex tube into the silica gel and install it on the neon tube.

![]()

Note: if the outlet mode of the light strip is waterproof joint or head, in this case, the wire shall be first passed through the plughole of the neon tube sleeve, then the wire shall be welded to the DC surface of the light strip, and finally silica gel shall be used to install the plug.

![]()

Key points of casing wearing:

1. The length of the led strip light must be measured carefully and the value must be accurate to ensure the best installation effect.

2. When pulling the light belt traction rope, be sure to put the light belt and the silicone tube straight without bending to ensure smooth penetration

3. Be sure to turn on the power to check whether the led light strip works normally after wearing the casing, so as to avoid unnecessary work.

4. Silica gel should be full, pay attention to the plug around the wall, and wire through the hole should be made of glue, so as to avoid a long time off the plug.

5. After the plug is installed, make sure that the silica gel is fully dried before using the neon light belt to ensure that the plug is stuck firmly.

There are a lot of new products that are not listed here in time. So, if you don’t find the style you want, or are interested in new silicone diffuser products, please send us a message and we’ll get back to you as soon as possible.