A new week coming , hope everyone have a good week.

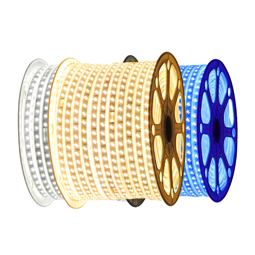

Today , I would like to have a brief introduce the production process of led strip light for everyone.

Firstly , before we use the led chip , we must make it dry enough in the oven , why we do this procedure , it is because the led chip will easy damage when they get wet.only in this way , we can gurantee the good quality of led chip.

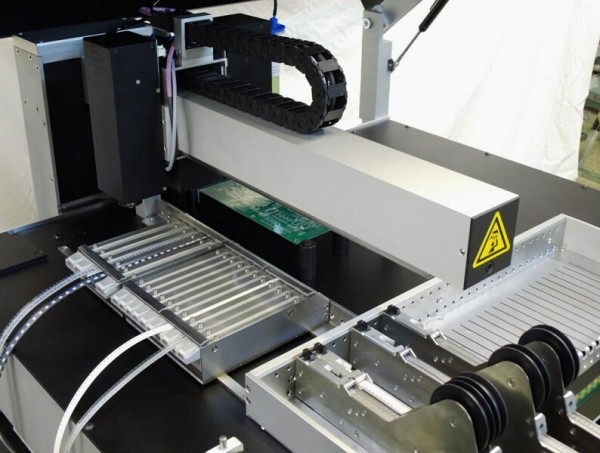

Secondly ,Before we put the pcb into SMD Machine to make chip on board , we must make tin silking on PCB board, So that the led chip can connected very well with the pcb .

Thridly , After the led chip on board in smd machine , we will put led strip to the reflowing soldering machine to make led chip connected fasten and better to PCB board , it is also a procedure to make tin and led chip on pcb try enough.

Fourth, after this process , we will see there are every half meter (0.5m) led strip come out from the reflowing soldering machine, then we will join each 0.5meter together to 5 meter . So now , the led strip is early to finish.

The last procedure is , we will make dc connectors or red/black wire on the end of led strip . the last but not the least is : we will take 24hours – 48 hours to make aging test before packing to ship .

We are the professional led strip factory , so when you read this article, please kindly give us a like . thank you so much .