SMD LED light craft April 19, 2010, the world’s most potential

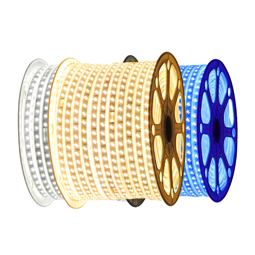

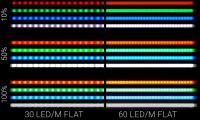

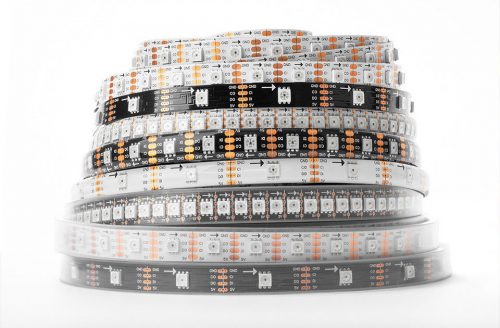

LED light bar is divided LED flexible light strip and LED soft light bar into two categories, the differences are as follows:

SMD LED lights manufacturing secondary concentrated in the Pearl River Delta, especially in Shenzhen, Dongguan, Zhongshan, Guangzhou and other places, no more than 100 production enterprises. Mainly private enterprises. If the domestic market consumption difficult enough, the market takeover is not high. The vast sector of its products for export, taking into account the domestic market.

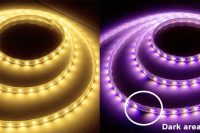

The use of materials that are waterproof light guessed, the market above more and more is the use of epoxy glue AB 560 series. But kind of glue package light bar across showing a bubble more, easy to break, intolerant of warm and cold weather, the sustainable use of the easy to turn yellow, easy to tear, and other defects. Chatting away with customers praise the most is the kind of glue. Division I is the glue of the polyurethane composition (PU Crystal). Polyurethane is a good adhesive, a lot of money, but brightly lit degree, frequently half 500 inexhaustible crack, tear-resistant, outdoor anti-UV permanent non-yellowing, profile glossy bad show, no worse than the same products made with low temperature resistance, water resistance, ozone, acid and alkali resistance, alcohol resistance, arc resistance, UV resistance, reincarnation hot and cold shock function, fully meet the high performance requirements of households use table.

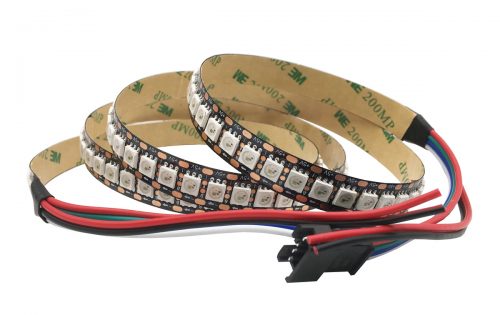

1, flexible SMD LED FPC do remove the circuit board, with SMD LED demolition, the thickness of the product is only the thickness of a soft money, does not occupy space; throughout the specification 30cm long 12 LED, 24 pcs LED and 15 LED 50cm long, 30 pieces of LED. Also 60cm, 80cm, different users no different specifications. And may easily cut, you can also perhaps willfully delay to emit light is not affected. FPC soft material, perhaps willfully bending, folding, winding, three-dimensional space easily move and stretch without breaking. Suitable for the use of the premises not the law of premises and space is at a premium, or if its perhaps the wanton bending and winding, suitable combination of various types of wanton advertising dotted pattern. It is worth recalling FPC segment material is divided into many categories, more than the force of the market with the above double-sided FPC is made of copper with sodium salt, of course, many companies also blind pursuit of a decline in the cost of materials, the adoption of the electrolyte to do into the FPC, the electrolyte FPC is welded Cheng Zhongrong difficult peeling caused indirectly by Weld and dead lights phenomenon, in addition to either from the conductive function flexibility electrolyte can not take the sub-salt copper compete.

From the beginning of 2000, because of the rapid growth of SMD LED light strip market began using LED lights as the use of optical flow. Range of times outdoor decoration, interior decoration, entertainment venues, as well as sectoral industrial equipment, automotive contour edge embellishment department the craft and disadvantages of the fruit LED itself, and soon replaced by neon lights, incandescent lamps and other conservative optical flow, later followed by the LED chip craft day mature harm, rich color change LED optical flow, higher brightness, especially power-saving, long life, environmental protection and other characteristics of bad show, SMD LED lights are outdoor embellishment lighting market with inferior said.